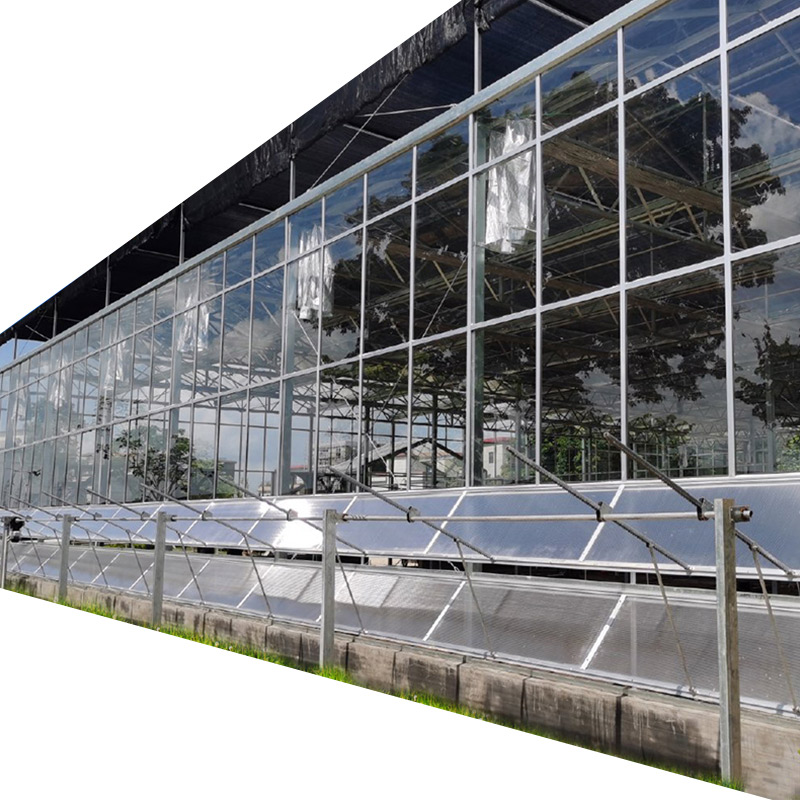

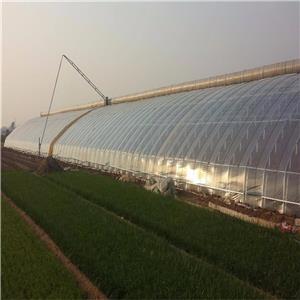

The advanced seedling glass greenhouse and steel structure glass greenhouse and steel structure glass greenhouse are designed by Fanhe provides a perfect controlled environment for commercial-scale plant propagation. Designed by horticultural experts, this professional structural feature: • seeding raising glass greenhouse hasPrecise climate control system to maintain the optimal temperature of 22-26°C and humidity of 65-75% \ n • Multi-layer propagation workbench with integrated tidal fall irrigation technology \ n •farm-style glass greenhouse has Intelligent shading system with adjustable aluminum screen light intensity management \ n • Supplementary LED growth lamps to ensure uniform PPFD distribution (150-300 μmol/m²/s).

Steel Structure Agricultural Seeding Raising Glass Greenhouse - The Ultimate Propagation Solution

1. Introduction to seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

In today,seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

form the foundation of successful crop cultivation. The Steel Structure Agricultural Seeding Raising Glass Greenhouse represents the pinnacle of propagation technology, combining structural durability, precise environmental control, and operational efficiency to deliver superior plant starts. This 3000-word guide explores every aspect of this advanced growing system.

2. Structural Design & Engineering Excellence in seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

2.1 Heavy-Duty Steel Framework

Galvanized steel construction with anti-corrosion treatment (200-300g/m² zinc coating)

Column-free spans of 8-12 meters for unobstructed workspace

Wind resistance up to 150km/h and snow load capacity of 0.5-0.75kN/m²

Modular design allowing expansion in 8m increments

2.2 Advanced Glazing System

4mm tempered horticultural glass with 91% light transmission

Anti-reflective coating to maximize PAR (Photosynthetically Active Radiation)

Thermal break aluminum glazing bars for condensation control

Safety features: Laminated glass options available

2.3 Specialized Propagation Infrastructure about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

Multi-tier benching systems (3-5 levels) with adjustable heights

Integrated root-zone heating (20-28°C precision control)

Automated shading/blackout systems for photoperiod management

Overhead service gantries for efficient workflow

3. Climate Control & Propagation Technology about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

3.1 Precision Environmental Management

Parameter | Control Range | Technology Used |

Temperature | 18-30°C (±0.5°C) | Hydronic heating + fogging |

Relative Humidity | 60-90% (±3%) | High-pressure mist system |

CO₂ Concentration | 400-1500ppm | Direct injection system |

Light Intensity | 0-300μmol/m²/s | Retractable LED supplementation |

3.2 Advanced Irrigation Systems

Ebb-and-flow benches with recirculating nutrient solution

Fog propagation for delicate cuttings (RH >90%)

Drip irrigation for grafted seedlings

Automated fertigation with EC/pH monitoring (accuracy ±0.1)

3.3 Energy Efficiency Features

Double-layer thermal screens (up to 40% energy savings)

Heat recovery ventilators (75% efficiency)

Solar-ready infrastructure for renewable integration

Phase-change materials for thermal buffering

4. Operational Workflow & Automation about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

4.1 Seedling Production Process

Seeding Station: Automated tray filling and sowing

Germination Chamber: 28°C/95% RH controlled environment

Primary Growth Area: LED-optimized light spectrum

Hardening Zone: Gradual acclimatization

Shipping Preparation: Automated grading and packagin

4.2 Smart Control Systems

IoT-enabled sensors monitoring each microclimate zone

Predictive algorithms for disease prevention

Automated material handling (seedling conveyor systems)

Remote monitoring via cloud-based platforms

4.3 Labor Efficiency Features

Ergonomic workstations at optimal height

Mobile seedling carts with RFID tracking

Automated labeling and inventory systems

Robotic transplanting options

5. Crop-Specific Applications about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

5.1 Vegetable Plug Production

Tomatoes/Peppers: 21-day production cycle

Leafy Greens: 12-15 day turnover

Cucurbits: Grafted seedling specialization

5.2 Ornamental Propagation

Annual bedding plants: Multi-variety trays

Perennial divisions: Specialized mist systems

Woody cuttings: Bottom heat configurations

5.3 Specialty Crops

Medicinal plants: Climate-zone isolation

Microgreens: Vertical stacking systems

Forestry seedlings: Boreal climate simulation

6. Economic Analysis & ROI about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

6.1 Cost Structure

Component | Cost per m² | Lifespan |

Steel Structure | 80−80−120 | 30+ years |

Glass Glazing | 60−60−90 | 20 years |

Climate Systems | 120−120−180 | 15 years |

Automation | 100−100−200 | 10 years |

Total Investment | 360−360−590/m² |

|

6.2 Operational Metrics

Annual production capacity: 500-800 trays/m²

Labor reduction: 40-60% vs conventional

Energy savings: 30-50% through efficiency features

Crop loss reduction: <5% vs industry average 15-20%

6.3 Financial Returns

Payback period: 3-5 years

ROI: 20-35% depending on crop value

Increased revenue: 15-25% from premium-quality seedlings

7. Case Studies & Real-World Performance7.1 Commercial Vegetable Nursery (Netherlands) about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

30,000m² operation producing 50 million tomato plugs annually

Energy neutral through geothermal + solar integration

98% germination rate achieved

7.2 Ornamental Producer (California)

Reduced labor costs by $1.2M/year through automation

Extended selling season from 8 to 11 months

Disease incidents reduced from 12% to <2%

7.3 Government Reforestation Project (Canada)

10 million conifer seedlings annually

30% faster growth versus outdoor beds

Year-round production in -40°C winters

8. Future Innovations & Trends about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

8.1 Emerging Technologies

AI vision systems for seedling quality grading

Blockchain tracking from seed to field

CRISPR-optimized varieties for greenhouse adaptation

8.2 Sustainability Developments

Closed-loop water systems with 95% recycling

Biodegradable growing media alternatives

Carbon capture integration through plant optimization

8.3 Market Expansion

Urban vertical propagation facilities

Pharmaceutical-grade medicinal plant production

Climate-resilient seedling development

9. Conclusion about seeding raising glass greenhouse ,steel structure glass greenhouse and farm-style glass greenhouse

The Steel Structure Agricultural Seeding Raising Glass Greenhouse represents the future of commercial plant propagation, combining engineering robustness, climate precision, and smart automation to deliver unprecedented quality and efficiency. Whether for large-scale vegetable production, specialty crops, or reforestation programs, this system provides complete environmental command while ensuring economic viability.

Ready to transform your seedling operation? Contact our engineering team for custom designs, turnkey solutions, and financing options tailored to your specific crop requirements and regional conditions.