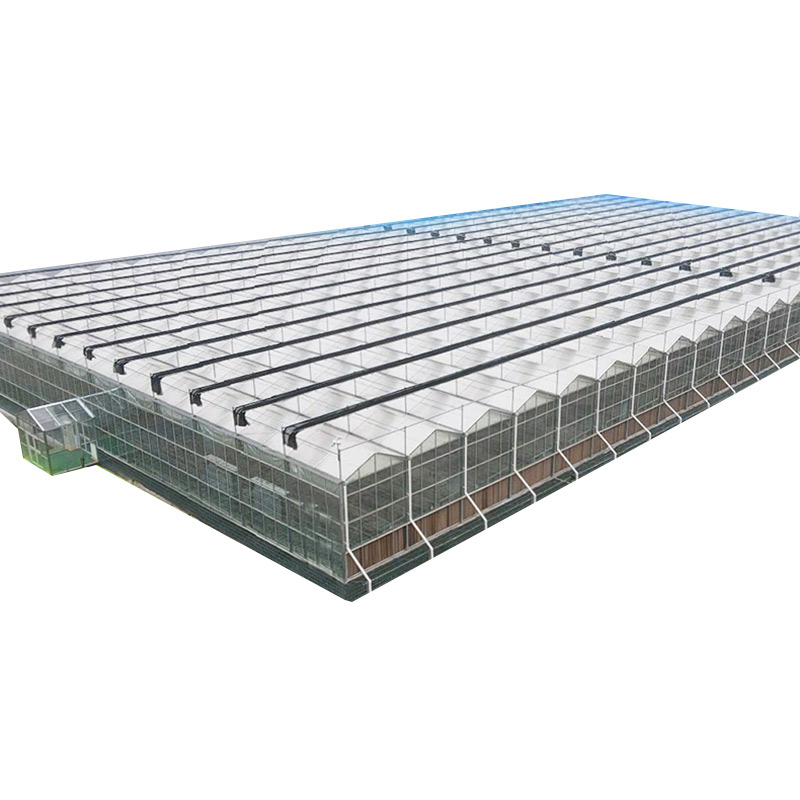

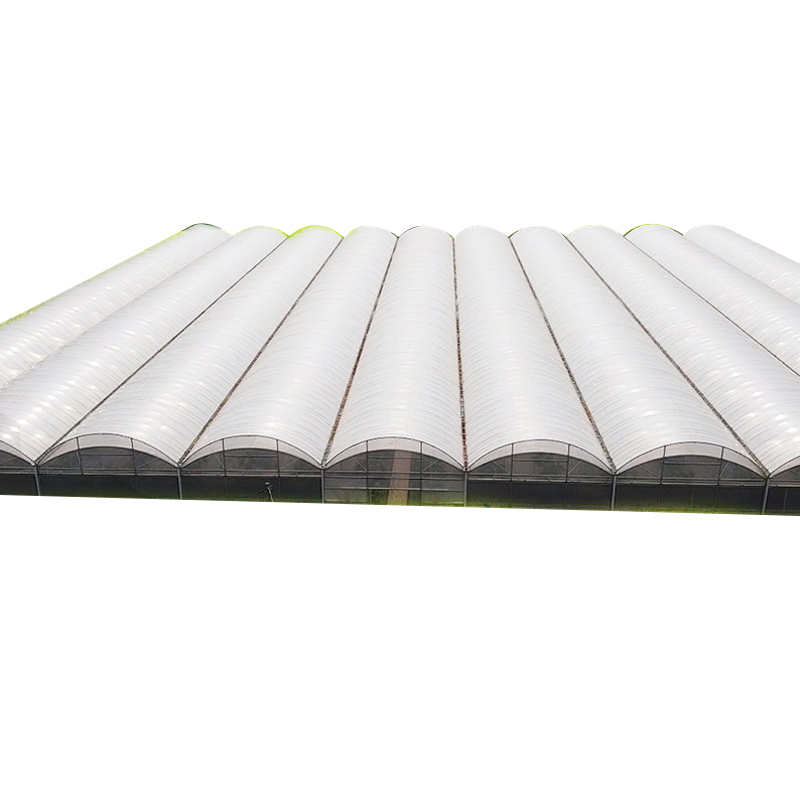

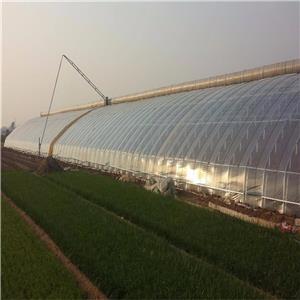

high light transmission polycarbonate greenhouse,linkage type polycarbonate greenhouse and steel structure polycarbonate greenhouse are engineered for crops requiring intense illumination, featuring ultra-clear multi-wall panels that deliver 90-94% visible light transmission – rivaling glass clarity while providing superior insulation and durability.

Hight Light Transmission Linked Steel Multi-layer Polycarbonate Greenhouse

1. Introduction to High Light Transmission Greenhouses and high light transmission polycarbonate greenhouse

High light transmission polycarbonate greenhouses represent the pinnacle of photosynthetic efficiency engineering, combining the clarity of glass with superior durability and insulation. These structures utilize advanced polymer formulations to achieve 90-94% visible light transmission – critical for crops like tomatoes, cannabis, and leafy greens where 1% more light = 1% higher yields (University of Wageningen, 2022).

Key Innovations of high light transmission polycarbonate greenhouse

Nano-coated surfaces reduce light refraction

Micro-prismatic diffusion layers eliminate shadows

UV-selective filtration protects plants while passing beneficial wavelengths

2. Optical Science of linkage type polycarbonate greenhouse , linkage type polycarbonate greenhouse and steel structure polycarbonate greenhouse

Light Transmission Mechanics

| Wavelength | Transmission % | Plant Impact |

|---|---|---|

| PAR (400-700nm) | 90-94% | Direct photosynthesis |

| UV-A (315-400nm) | 0% (blocked) | Prevents DNA damage |

| Far-Red (700-800nm) | 88% | Stimulates flowering |

Comparative Performance

| Material | Light Transmission | Haze % | 10-Year Degradation |

|---|---|---|---|

| Glass | 92% | 0% | 2-3% loss |

| Standard PC | 82% | 25% | 15% loss |

| High-Tech PC | 93% | 12% | <5% loss |

3. Structural Advantages of linkage type polycarbonate greenhouse and steel structure polycarbonate greenhouse

Versus Glass:

✔ 200x more impact resistant (ASTM D256)

✔ 50% lighter weight (3kg/m² vs 6kg/m²)

✔ 3x better thermal insulation (U-value 1.0 vs 3.0)

Versus Polyethylene:

✔ 10x longer lifespan (15-20 years vs 2-3)

✔ 85% less condensation

✔ Precision spectral control

4. Multi-Wall Panel Technology

Panel Types Comparison of linkage type polycarbonate greenhouse and steel structure polycarbonate greenhouse

| Type | Light Transmission | R-Value | Best Use |

|---|---|---|---|

| 4mm Twin-Wall | 88% | 1.7 | Mild climates |

| 6mm Triple-Wall | 86% | 2.3 | 4-season growing |

| 16mm X-Structure | 84% | 3.5 | Arctic conditions |

Innovative Features of steel structure polycarbonate greenhouse

Laser-cut ventilation channels (reduce light blockage)

Anti-dust coatings (maintain >90% clarity for 5+ years)

Prismatic light guides (redirect low-angle winter light)

5. Light Spectrum Optimization of steel structure polycarbonate greenhouse

Crop-Specific Recipes:

Tomatoes (High-Light Varieties):

DLI Requirement: 25-30 mol/m²/day

Spectral Enhancements:

15% blue boost (450nm) for compact growth

Far-red priming at sunset

Cannabis (Medical Grade):

UV-B Exclusion: Blocks <300nm to prevent THC degradation

IR Rejection: Reduces cooling loads

6. Thermal Performance

Insulation Metrics:

U-value: 0.58 W/m²K (triple-wall)

Condensation Resistance: 0.85 (1=perfect)

Solar Heat Gain Coefficient: 0.78

Energy Savings:

40% reduction in heating costs vs glass

6-8°C warmer than PE film at night

7. Durability Testing

Hail Resistance: Passes 2" ice ball @ 90mph (UL 2218 Class 4)

Wind Load: 130mph certification (Miami-Dade County)

Fire Rating: B1 (DIN 4102)

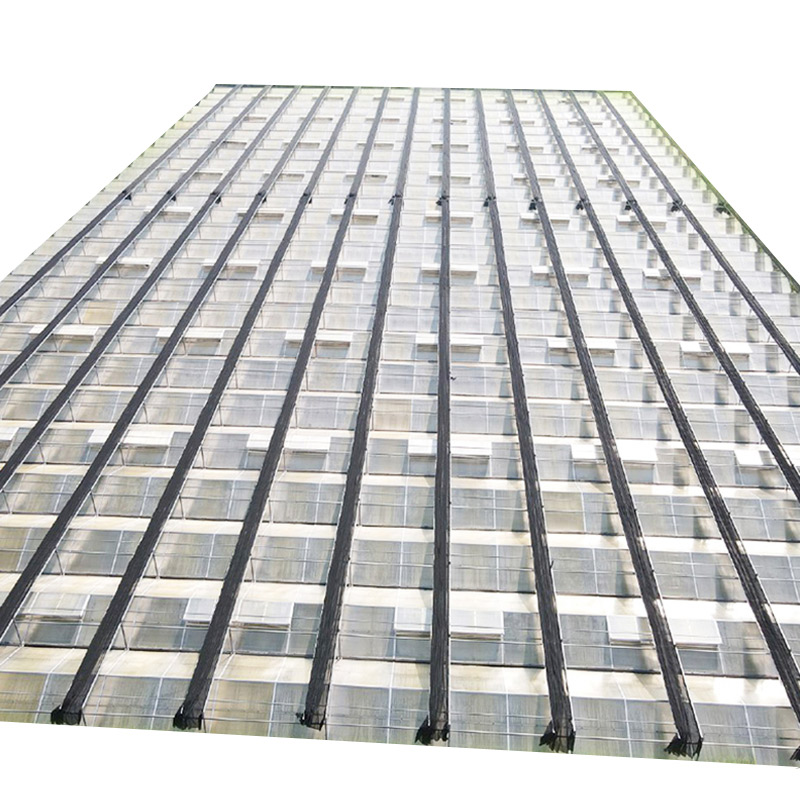

8. Commercial Crop Designs

Tomato Greenhouse:

Panel Type: 8mm clear twin-wall

Light Augmentation: Movable shade screens (40% Aluminet)

Yield Increase: 22% over standard PC

Cannabis Facility:

Light Diffusion: 15° haze for canopy penetration

Security: Opaque lower walls + clear roof

9. UV Management

100% UV-A/B blocking protects plants/polymer

Controlled UV-C zones for sterilization

10. Condensation Control

Hydrophobic nano-coatings (contact angle >110°)

Channeled condensate drainage

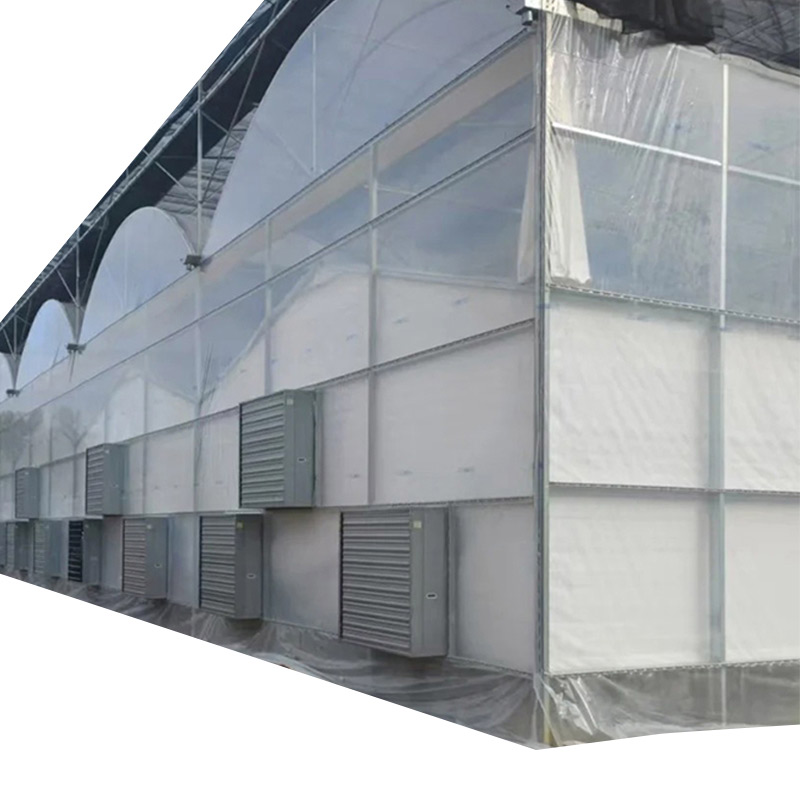

11. Ventilation Integration

Automated ridge vents (30% airflow boost)

Light-preserving sidewalls (mesh vs solid)

12. Climate Adaptations

Desert Regions:

IR-reflective outer layers

Sand-resistant surface treatments

Nordic Locations:

Snow-load optimized frames

Light-redirecting prism panels

13. Installation Protocols

Foundation: Laser-leveled aluminum rails

Panel Mounting: Thermal-break gaskets

Sealing: Silicone-free EPDM gaskets

14. Maintenance

Annual: Photometric testing

5-Year: Anti-condensation coating refresh

15. Yield Studies

| Crop | Yield Increase | Energy Savings |

|---|---|---|

| Tomatoes | +19% | 38% |

| Lettuce | +27% | 42% |

| Roses | +15% | 31% |

16. Energy Analysis

Annual PV Potential: 35kWh/m² (solar-ready roofs)

Light Loss Compensation: 8% less supplemental LED needed

17. Cost Breakdown

| Component | Cost Premium | Payback Period |

|---|---|---|

| High-Tech Panels | +15% | 2.3 years |

| Optical Coatings | +8% | 1.1 years |

18. Automation

Light sensors trigger dynamic shading

Self-cleaning panels (electrostatic)

19. Photon-Efficient Crops

Top Performers:

Cherry tomatoes

Basil

Chrysanthemums

20. Case Studies

Netherlands Tomato Farm:

5ha high-light PC greenhouse

31kg/m² annual yield (vs 25kg industry avg)

21. Future Innovations

Quantum dot-enhanced panels (spectral shifting)

Self-healing surfaces

22. Troubleshooting

Issue: 5% annual light loss

Solution: Replace anti-reflective coating

23. Certifications

ISO 14025 (environmental impact)

CE EN 16983 (optical performance)

24. FAQs

Q: How often should light transmission be tested?

A: Annually with a PAR meter

25. Conclusion

High light transmission polycarbonate greenhouses deliver unmatched photosynthetic efficiency, durability, and climate control – making them the premier choice for commercial growers where light equals profit.