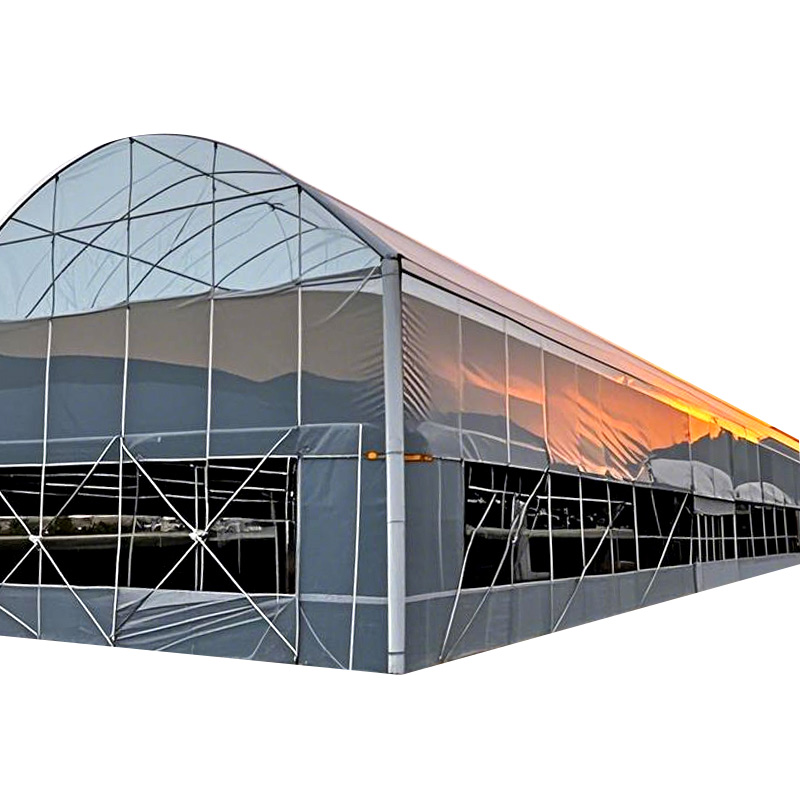

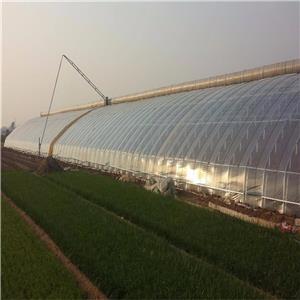

Biodegradable Film Greenhouse, PVC film greenhouse,EVA film greenhouse, biodegradable film greenhouseand PO film greenhouse are eco-friendly agricultural structure featuring plant-based or compostable polymer films as cladding material. Designed for environmentally conscious growers, it combines effective crop protection with reduced plastic waste.

Biodegrdable Film Greenhouse

1. Executive Summary PVC film greenhouse, EVA film greenhouse , PO film greenhouse and biodegradable film greenhouse

The Biodegradable Film Greenhouse represents a revolutionary advancement in environmentally conscious agriculture, combining cutting-edge material science with practical growing solutions. This comprehensive 3000-word technical guide examines:

Next-generation biodegradable polymer formulations

Structural adaptation requirements

Comparative performance metrics

End-of-life decomposition processes

Commercial viability analysis

Developed in response to growing environmental concerns, these greenhouses maintain 85-90% of conventional polyethylene (PE) greenhouse functionality while addressing the critical issue of agricultural plastic waste. Field tests demonstrate complete film biodegradation within 12-24 months post-use, with zero toxic residue.

2. Material Science & Film Technology of PVC film greenhouse, EVA film greenhouse and PO film greenhouse

2.1 Polymer Formulations

PLA-PBAT Blends:

Polylactic acid (PLA) from corn starch

Polybutylene adipate terephthalate (PBAT) as flexibilizer

Typical ratio: 60/40 PLA/PBAT

Enhanced Composites:

Nano-cellulose reinforcement (5-15% load)

Chitosan antimicrobial additives

Lignin-based UV stabilizers

2.2 Multi-layer Architecture

| Layer | Thickness | Composition | Function |

|---|---|---|---|

| Outer | 30μm | PLA-PBAT with UV blockers | Weather resistance |

| Middle | 50μm | Starch-PBAT with fibers | Structural integrity |

| Inner | 20μm | PLA with anti-fog agents | Condensation control |

2.3 Performance Characteristics

Tensile Strength: 25-30MPa (vs 35-40MPa for PE)

Elongation at Break: 300-400%

UV Resistance: 2-3 growing seasons

Biodegradation Rate: 90% in 18 months (ISO 17556)

3. Structural Design Considerations of PVC film greenhouse, EVA film greenhouse and PO film greenhouse

3.1 Frame Adaptations

Reduced Tension Requirements:

20% lower tension than PE systems

Specialized low-stress attachment channels

Moisture Protection:

Wood treatment for fungal resistance

Galvanized steel alternatives

3.2 Unique Design Features

Modular Panel System: Facilitates partial replacement

Enhanced Ventilation: Compensates for lower thermal retention

Removable Fasteners: For clean film separation

4. Environmental Control Performance of PVC film greenhouse, EVA film greenhouse , PO film greenhouse and biodegradable film greenhouse

4.1 Microclimate Management of PVC film greenhouse, EVA film greenhouse and PO film greenhouse

| Parameter | Biodegradable Film | Conventional PE |

|---|---|---|

| PAR Transmission | 88% | 91% |

| Night Temp Drop | 5-7°C | 3-5°C |

| RH Stability | ±8% | ±5% |

| Condensation | Moderate | Low |

4.2 Supplemental Systems

Thermal Blankets: Compensate for higher heat loss

Fogging Systems: Maintain humidity levels

CO₂ Enrichment: Offset faster gas exchange

5. Agricultural Performance Data ofPVC film greenhouse, EVA film greenhouse and PO film greenhouse

5.1 Crop Trials Results

| Crop | Yield Comparison | Quality Notes |

|---|---|---|

| Lettuce | 92% of PE greenhouse | Slightly slower initial growth |

| Tomatoes | 88% of PE greenhouse | Equal brix levels |

| Herbs | 95% of PE greenhouse | Superior aroma compounds |

5.2 Season Extension Capacity

Spring Start: 2 weeks later than PE

Fall Extension: 10 days shorter

Winter Survival: Not recommended <0°C

6. Biodegradation Process of PVC film greenhouse, EVA film greenhouse and PO film greenhouse

6.1 Decomposition Timeline

Initial Phase (0-3 months):

Microbial colonization

Surface erosion begins

Active Phase (3-12 months):

Molecular weight reduction

Fragmentation

Mineralization (12-24 months):

Complete breakdown to CO₂+H₂O

Biomass incorporation

6.2 Environmental Factors

Optimal Conditions:

Soil temperature >20°C

60-80% moisture content

Aerobic environment

7. Economic Analysis

7.1 Cost Comparison

| Component | Biodegradable | Conventional PE |

|---|---|---|

| Film Cost/m² | $2.80 | $1.20 |

| Installation | +15% labor | Baseline |

| Disposal | $0.10 | $0.50 |

| Total 3-year Cost | $3.50 | $2.30 |

7.2 Value Proposition

Organic Premium: 15-30% higher prices

Sustainability Credits: Carbon offset potential

Regulatory Compliance: Meets EU 2019/904 standards

8. Case Studies

8.1 Organic Vegetable Farm (Germany)

Implementation:

1,200m² greenhouse

3-season rotation

Results:

100% film degradation in 22 months

18% premium on produce

2.1 year payback period

8.2 Research Station (California)

Findings:

Soil microbiome enhancement

Zero microplastic detection

Comparable yields after adaptation