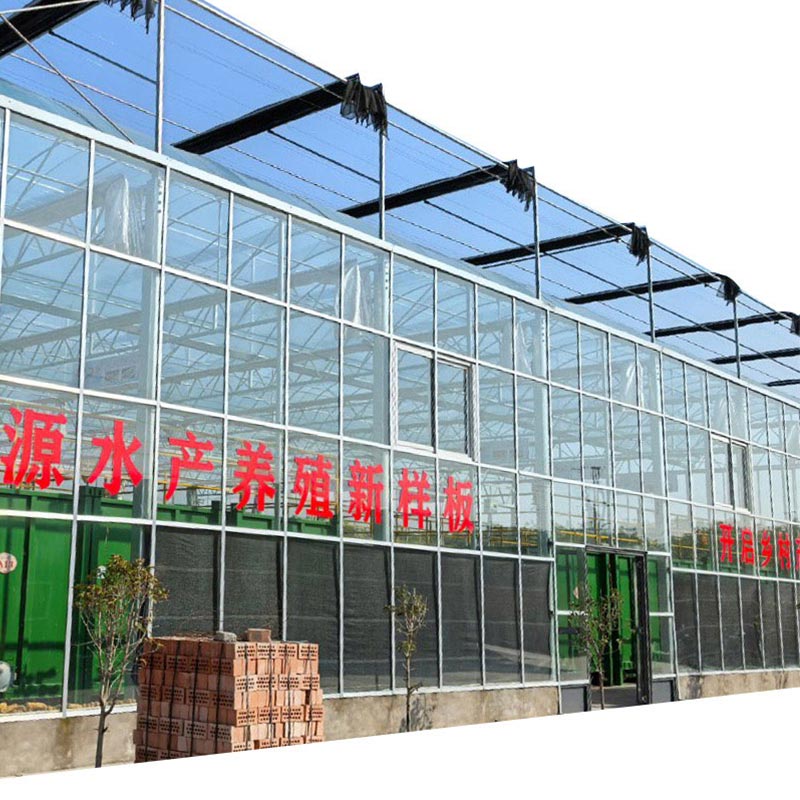

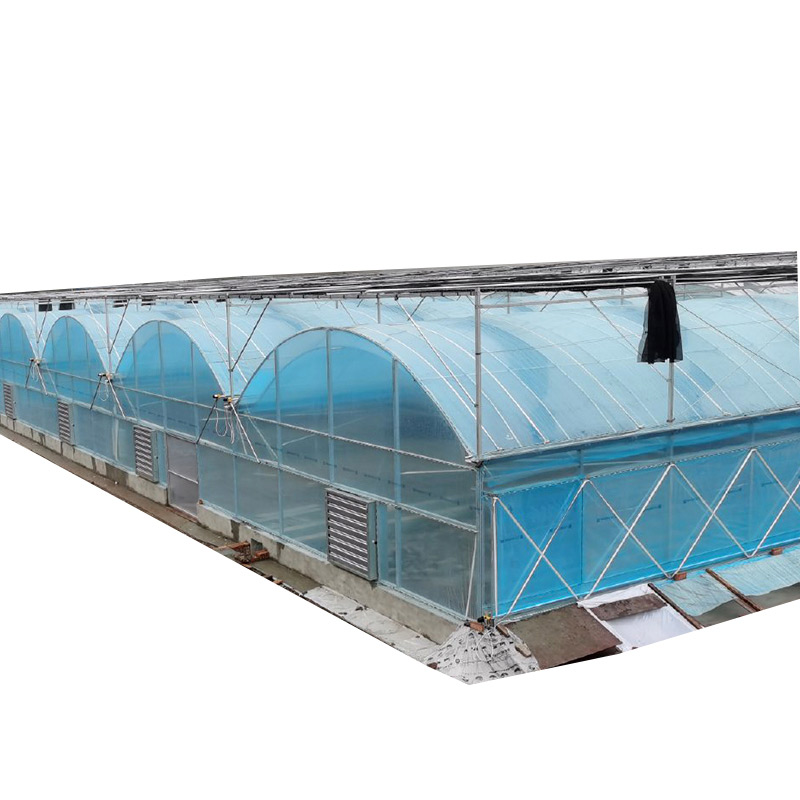

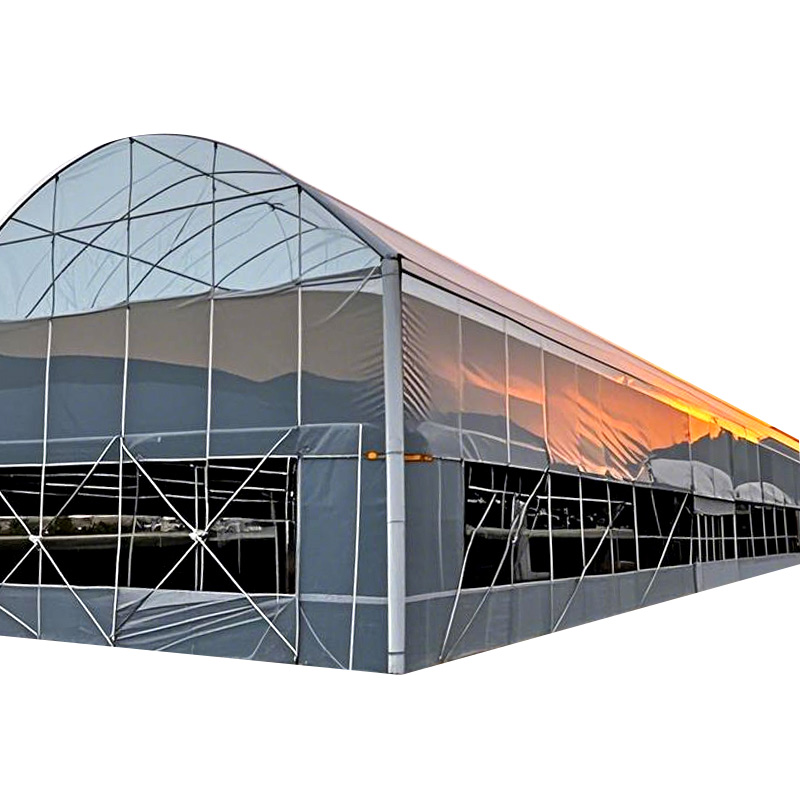

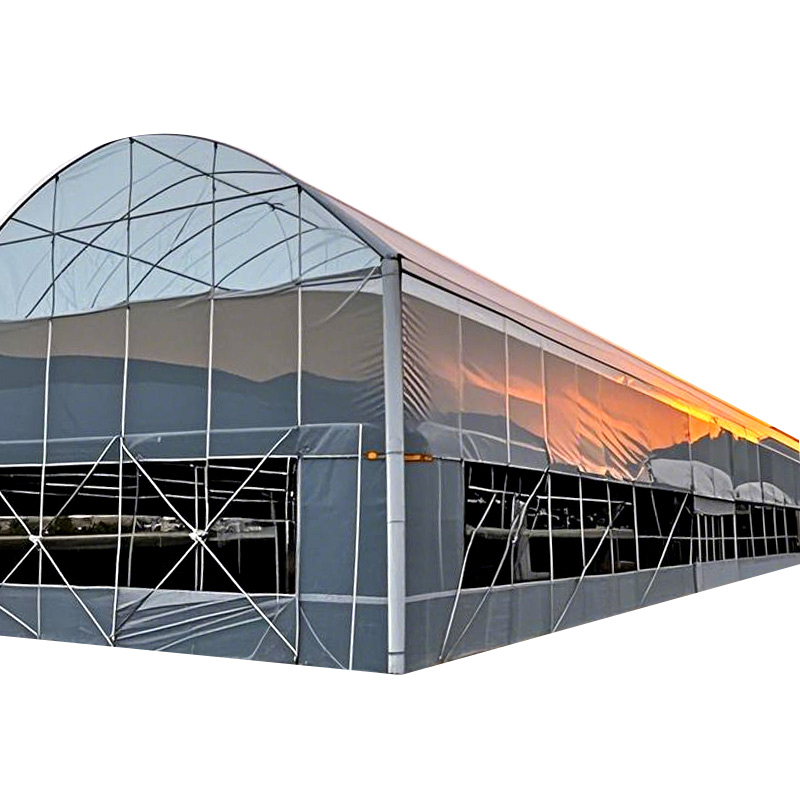

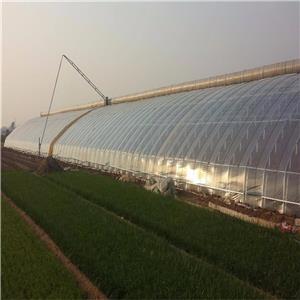

polythylene plastic greenhouse ,multi-span film greenhouse and single-span film greenhouseare cost-effective, versatile structure designed for year-round crop production. Made from UV-stabilized PE film, it provides durable protection against weather while optimizing light diffusion for plant growth.

Swatooth-shaped Film Greenhouse

1. Executive Summary of polythylene plastic greenhouse and multi-span film greenhouse

The polyethylene plastic greenhouse represents one of the most widely adopted protected agriculture systems globally, offering an optimal balance between cost-effectiveness and functional performance. This 3000-word technical manual provides a complete analysis of modern PE greenhouse technology, examining:

Material science advancements in polyethylene films

Structural engineering principles

Microclimate management systems

Comparative performance metrics

Commercial implementation strategies

Developed through decades of agricultural engineering refinement, today's PE greenhouses deliver 80-90% of glass greenhouse functionality at just 20-30% of the capital cost, with recent technological innovations extending film lifespan from 2-3 years to 5-8 years.

2. Material Science of Polyethylene Films of polythylene plastic greenhouse

2.1 Polymer Composition of single-span film greenhouse

Base resin: Linear low-density polyethylene (LLDPE)

Additive packages of single-span film greenhouse

UV stabilizers (HALS compounds)

Anti-fog agents (glycerol esters)

IR blockers (silicate particles)

Antimicrobial compounds (nano-silver)

2.2 Multi-Layer Construction

| Layer | Thickness | Function |

|---|---|---|

| Outer | 50μm | UV protection, abrasion resistance |

| Middle | 30μm | IR absorption, strength reinforcement |

| Inner | 20μm | Anti-condensation, light diffusion |

2.3 Optical Properties

PAR transmission: 88-92% (400-700nm)

Light diffusion: 30-50% haze

UV-B blocking: 95-98%

Thermal retention: 60-70% IR radiation

3. Structural Design Engineering of polythylene plastic greenhouse,single-span film greenhouse

3.1 Frame Systems

Pipe-frame design:

Galvanized steel (Φ32-50mm)

Spacing: 0.8-1.2m between arches

Snow load capacity: 30-50kg/m²

Truss-frame design:

Triangular truss configuration

Span width: 8-12m without columns

Wind resistance: 100-120km/h

3.2 Foundation Options of single-span film greenhouse

Ground posts: 60cm depth concrete

Anchor system: Screw-in ground anchors

Perimeter base: Concrete curb 20×30cm

4. Environmental Control Systems of polythylene plastic greenhouse,multi-span film greenhouse

4.1 Ventilation Technology of single-span film greenhouse

Roof vents:

Continuous ridge vent design

15-25% of floor area

Manual or automatic operation

Side vents:

Roll-up curtain system

1.0-1.5m opening height

Insect netting integration

4.2 Temperature Management

Passive heating:

Thermal screens (R-value 1.5-2.0)

Water barrel heat storage

Active heating:

Air heaters (30,000-50,000kcal/h)

Soil heating cables

5. Performance Data Analysis of polythylene plastic greenhouse,multi-span film greenhouse

5.1 Durability Testing

| Test Parameter | Performance | Industry Standard |

|---|---|---|

| UV resistance | 5-8 years | 2-3 years |

| Tensile strength | 28MPa | 22MPa |

| Tear resistance | 120N/mm | 80N/mm |

| Haze change | <5% after 3 years | 15-20% |

5.2 Crop Production Metrics of single-span film greenhouse

| Crop | Yield Increase | Quality Improvement |

|---|---|---|

| Tomato | 25-35% | 20% higher brix |

| Cucumber | 30-40% | 15% straighter fruit |

| Lettuce | 40-50% | 30% less tipburn |

| Pepper | 20-30% | Improved color |

6. Installation & Maintenance of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

6.1 Construction Process

Site preparation (2-3 days)

Leveling and drainage

Foundation installation

Frame assembly (5-7 days)

Arch erection

Purlin installation

Bracing completion

Film covering (2-3 days)

Unrolling and positioning

Tensioning and securing

Edge trimming

6.2 Maintenance Protocol

Daily: Ventilation adjustment

Weekly: Film surface cleaning

Monthly: Structural inspection

Annual: Film replacement (as needed)

7. Economic Analysis of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

7.1 Cost Structure Comparison

| Component | PE Greenhouse | Glass Greenhouse |

|---|---|---|

| Structure | $8-12/m² | $35-50/m² |

| Covering | $1.5-2.5/m² | $25-40/m² |

| Systems | $5-8/m² | $15-25/m² |

| Total | $15-23/m² | $75-115/m² |

7.2 ROI Calculation

Capital cost: $18/m² (average)

Annual production value: $45-60/m²

Payback period: 0.8-1.2 years

8. Technological Innovations of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

8.1 Advanced Film Technologies

Nano-composite films:

Self-cleaning surfaces

Photoselective wavelength filtration

Electrostatic dust repellency

Smart films:

Temperature-responsive opacity

Light spectrum adjustment

Self-repairing microcapsules

8.2 Structural Advancements

Retractable roof systems

Movable gutter designs

Foldable sidewalls

9. Global Case Studies of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

9.1 Mediterranean Vegetable Production

Location: Almeria, Spain

Scale: 30,000 hectares

Results:

10-month production cycle

90% water use efficiency

35kg/m² annual yield

9.2 Asian Tropical Cultivation

Location: Shouguang, China

Achievements:

Typhoon resistance verified

5-year film lifespan achieved

12 crop cycles annually

10. Future Development Trends of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

10.1 Material Science

Biodegradable PE alternatives

Graphene-enhanced films

Phase-change material integration

10.2 Automation

Robotic film replacement

AI-based microclimate control

Drone-assisted monitoring

11. Conclusion of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

The modern polyethylene plastic greenhouse has evolved into a sophisticated agricultural tool that delivers:

Exceptional cost-performance ratio

Advanced environmental control

Reliable crop protection of polythylene plastic greenhouse,multi-span film greenhouse and multi-span film greenhouse

With continuous innovations in material science and engineering design, PE greenhouses will remain the backbone of protected agriculture worldwide, particularly for small-to-medium scale commercial operations seeking balanced capital investment and production returns.