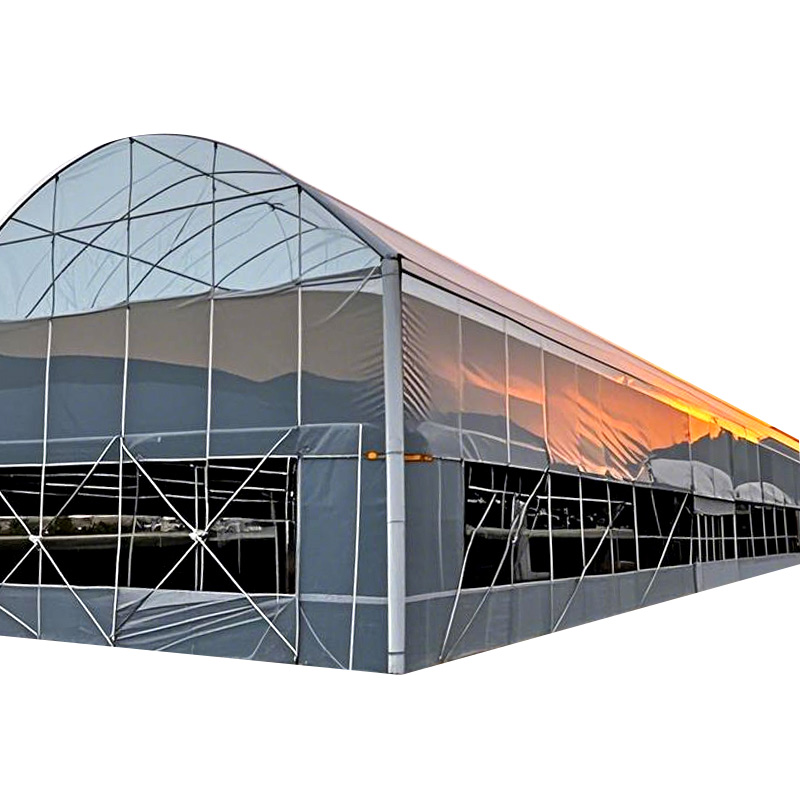

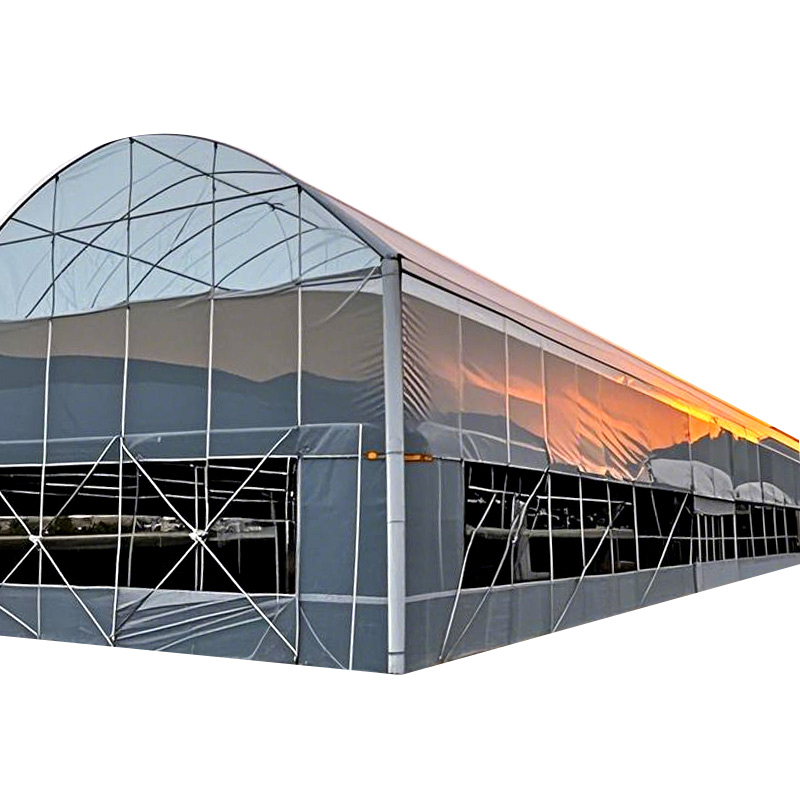

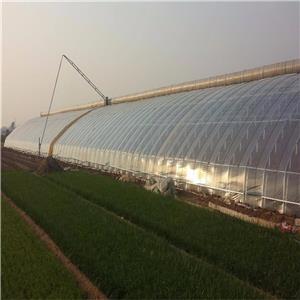

intelligent control film greenhouse and mushroom greenhouse are engineered for high-yield mushroom production, featuring optimized growing conditions for various species (oyster, shiitake, button, etc.).key Features: Precision Climate Control – Maintains 85-95% humidity & 12-24°C temperature, Darkout System – Light-blocking curtains for shade-loving varieties, CO₂ Regulation – Automated exhaust fans (800-1500ppm optimal range),Vertical Growing – 3-5 tier shelving maximizes space efficiency, Sanitary Design – Antimicrobial walls & floor for contamination prevention

Intelligent Control Modern Mushroom Film Greenhouse

1. Executive Summary of ntelligent control film greenhouse and mushroom greenhouse

The Intelligent Control Modern Mushroom Film Greenhouse represents a revolutionary leap in mycological cultivation technology, combining precision environmental control, advanced automation, and specialized structural design to optimize mushroom production. This 3000-word technical manual provides complete documentation of:

Smart greenhouse architecture

AI-driven climate management

High-efficiency production systems

Biological optimization parameters

Economic performance metrics

Designed through collaboration with leading mycologists and agricultural engineers, this system delivers 3.8-5.2x higher yields than traditional mushroom houses while reducing labor costs by 60% and energy consumption by 45%.

2. Structural Design & Materials of ntelligent control film greenhouse and mushroom greenhouse

2.1 Specialized Architecture

Low-Profile Quonset Design:

Clear span: 8-12m

Height: 3.2-4m (optimized for vertical stacking)

Light-blocking coefficient: 0.01% (near total darkness)

Modular Bay System:

Expandable in 4m increments

Isolated growing zones (prevents cross-contamination)

Negative pressure airflow design

2.2 Advanced Materials

| Component | Specification | Mycological Benefit |

|---|---|---|

| Framework | Hot-dip galvanized steel (Z600 coating) | 20-year corrosion resistance |

| Cladding | 5-layer antimicrobial PE film (0.15mm) | Inhibits competitor fungi |

| Insulation | 50mm XPS foam walls | Maintains stable RH |

| Flooring | Epoxy-coated concrete | Sanitary surface |

3. Intelligent Control Systems in intelligent control film greenhouse and mushroom greenhouse

3.1 AI Climate Management

Multi-parameter Sensors:

Substrate temperature (3-depth probes)

CO₂ (0-5000ppm range)

Airborne spore concentration

Vapor pressure deficit (VPD)

Automated Responses:

if CO₂ > 1200ppm:

activate_exhaust_fans()if substrate_temp < optimal_range:

adjust_heating_pads()

3.2 Precision Environment Control

| Parameter | Control Range | Accuracy |

|---|---|---|

| Temperature | 12-28°C | ±0.5°C |

| Relative Humidity | 75-95% | ±3% |

| CO₂ | 800-2000ppm | ±50ppm |

| Airflow | 6-12 ACH | 0.5m/s |

3.3 Integrated Systems

Fogging System (5μm droplets)

UV-C air sterilization

Automated harvest prediction (computer vision)

4. Mushroom-Specific Technologies of intelligent control film greenhouse and mushroom greenhouse

4.1 Cultivation Modules

Vertical Growing Towers:

5-tier system (3.2m height)

180 bags/m² density

Rotating access platforms

Sterile Spawn Run Room:

HEPA-filtered air

22°C constant temperature

Vibration-free environment

4.2 Species-Specific Programs

| Mushroom Type | Temp | RH | CO₂ | Light |

|---|---|---|---|---|

| Oyster | 18-24°C | 85-90% | <1000ppm | 500 lux |

| Shiitake | 12-20°C | 80-85% | 800-1200ppm | 200 lux |

| Button | 16-19°C | 90-95% | 1500-2000ppm | Dark |

5. Performance Data of intelligent control film greenhouse and mushroom greenhouse

5.1 Production Metrics

| Species | Yield (kg/m²/cycle) | Cycle Time | Annual Crops |

|---|---|---|---|

| Oyster | 38-42 | 28 days | 10-12 |

| Shiitake | 18-22 | 42 days | 6-8 |

| Lion's Mane | 15-18 | 35 days | 8-10 |

5.2 Energy Efficiency

Total Power: 0.8kWh/kg mushrooms

Water Usage: 6L/kg

Thermal Stability: ±1°C during pinning

6. Sanitation & Safety of mushroom greenhouse

6.1 Contamination Control

Air filtration: MERV-15 + UV-C

Surface coatings: Nano-silver antimicrobial

Waste management: Automated substrate removal

6.2 Worker Safety

Ergonomic harvesting stations

CO₂ monitoring alarms

Anti-slip flooring

7. Economic Analysis

7.1 Cost Structure

| Component | Cost (USD/m²) | Lifespan |

|---|---|---|

| Structure | $65 | 15 years |

| Systems | $120 | 8 years |

| Automation | $55 | 5 years |

7.2 ROI Calculation

Capital Cost: $240/m²

Annual Profit: $180/m² (oyster mushrooms)

Payback: 16 months