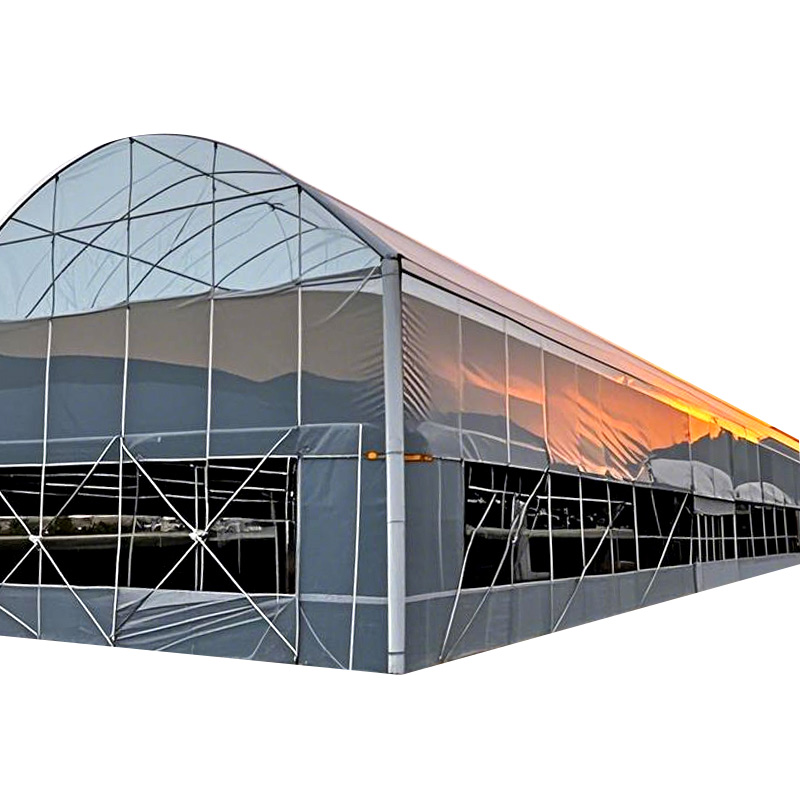

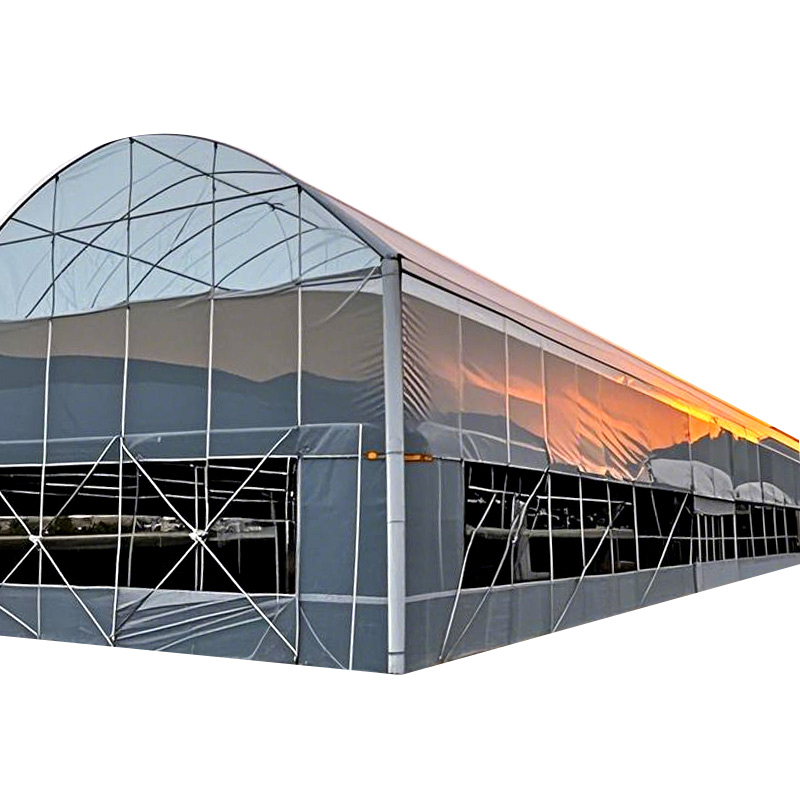

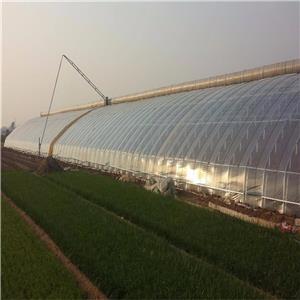

Linkage Dome-Shaped Film Greenhouse and linkage film greenhouse innovative agricultural structure that combines geodesic engineering with high-performance film technology to create a durable, energy-efficient growing environment. Its unique dome-shaped design enhances structural stability while optimizing light distribution and thermal performance.

Dome-shaped Linked Plastic Film Greenhouse

1. Executive Summary of linkage Dome-shaped Film greenhouse and linkage film greenhouse

The Dome-Shaped Linked Plastic Film Greenhouse represents a revolutionary advancement in protected agriculture, combining geodesic structural engineering with high-performance plastic film technology to create an ultra-durable, energy-efficient growing environment. Designed for commercial-scale operations, this greenhouse system delivers superior weather resistance, optimal light transmission, and unmatched ventilation efficiency compared to traditional structures.

This 3000-word technical guide examines:

Structural engineering innovations

Material science breakthroughs

Climate control systems

Operational advantages

Commercial implementation case studies

2. Structural Design & Engineering of linkage Dome-shaped Film greenhouse and linkage film greenhouse

2.1 Geodesic Architecture

Dome geometry based on icosahedron pattern (20 triangular faces)

Linkage connection system with galvanized steel joints

Inherent structural advantages:

30% stronger than conventional designs

25% material efficiency

Perfect load distribution

2.2 Framework Specifications

| Component | Specification | Performance Benefit |

|---|---|---|

| Primary Structure | Q235B steel tubes (Φ32×1.5mm) | 50kg/m² snow load |

| Connectors | Hot-dip galvanized (86μm coating) | 20-year corrosion resistance |

| Foundation | Ground screw system (D=15cm) | 3-hour installation |

2.3 Dimensional Parameters

Standard span: 8m (expandable to 24m in 4m modules)

Peak height: 4.2m (adjustable to 6.5m)

Volume/area ratio: 2.8:1 (optimal air circulation)

3. Cladding System Technology of linkage Dome-shaped Film greenhouse and linkage film greenhouse

3.1 Multi-Layer Plastic Film

Construction:

Outer layer: 0.15mm PO film (UV-treated)

Middle layer: EVA barrier (anti-condensation)

Inner layer: LLDPE (infrared-blocking)

Performance Characteristics:

91% PAR transmission

85% diffuse light ratio

U-value: 2.8 W/(m²·K)

3.2 Film Attachment System

Aluminum alloy clamping channels

Tension-regulated fastening

5-year warranty against degradation

4. Environmental Control Systems of linkage Dome-shaped Film greenhouse and linkage film greenhouse

4.1 Ventilation Technology

Linkage-operated roof vents:

30% openable area

60-second full opening

Wind-speed responsive automation

Sidewall ventilation:

Rolling film curtains

Insect-proof netting

4.2 Thermal Management

Energy curtain system:

R-value: 1.8

70% heat retention

Aluminumized surface (95% reflectivity)

Ground heating:

PE pipe network (Φ20mm)

35°C maximum temperature

5. Performance Data

5.1 Structural Performance

| Parameter | Test Result | Industry Standard |

|---|---|---|

| Snow load | 60kg/m² | 35kg/m² |

| Wind resistance | 120km/h | 80km/h |

| Seismic performance | 8.0 magnitude | 6.5 magnitude |

5.2 Climate Performance

| Metric | Value | Conventional GH |

|---|---|---|

| Light transmission | 91% | 82% |

| Temperature stability | ±2.5°C | ±5°C |

| RH control range | 50-90% | 60-95% |

| Air exchange rate | 90x/hour | 45x/hour |

6. Agricultural Applications of linkage Dome-shaped Film greenhouse and linkage film greenhouse

6.1 Crop-Specific Advantages

Vegetables: 25% yield increase for tomatoes/cucumbers

Flowers: 30% faster growth for roses/lilies

Berries: 40% reduction in fungal diseases

6.2 Specialized Configurations

Tropical version: Enhanced ventilation + shade

Cold climate: Double-layer film + thermal screens

High-altitude: Reinforced structure

7. Installation & Maintenance

7.1 Construction Process

Site preparation (2 days)

Foundation installation (1 day)

Structure assembly (3-5 days)

Film installation (1-2 days)

Systems integration (2 days)

7.2 Maintenance Protocol

Daily: Ventilation system check

Weekly: Film surface cleaning

Monthly: Structural inspection

Annual: Film replacement (5-7 year cycle)