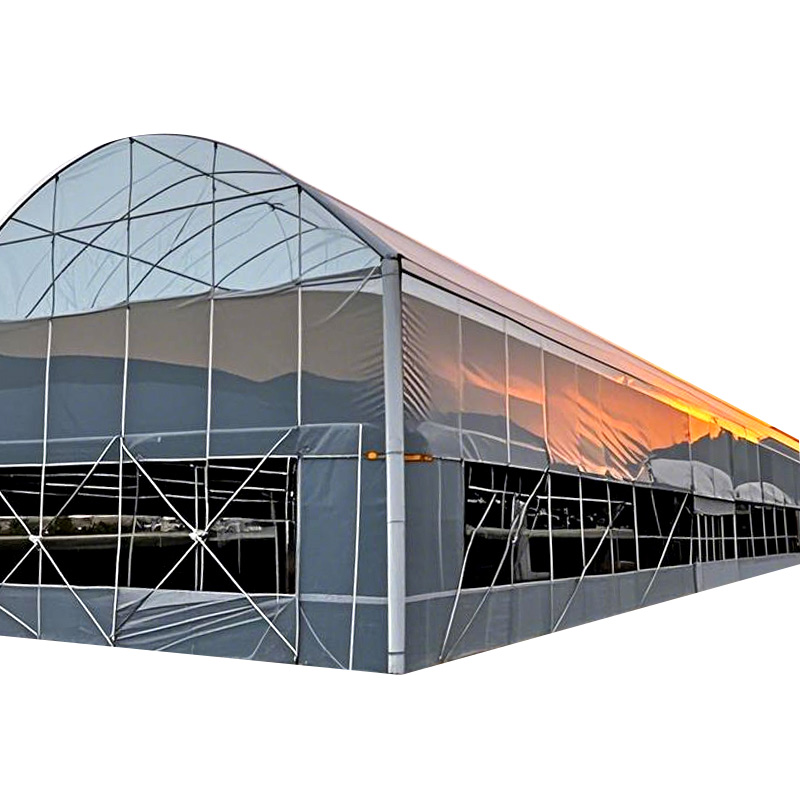

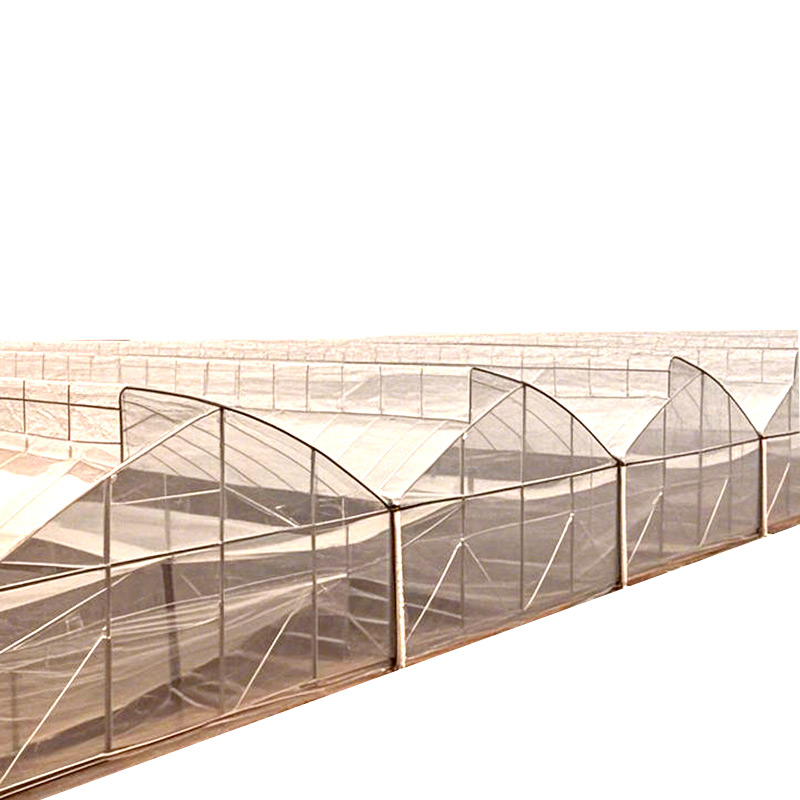

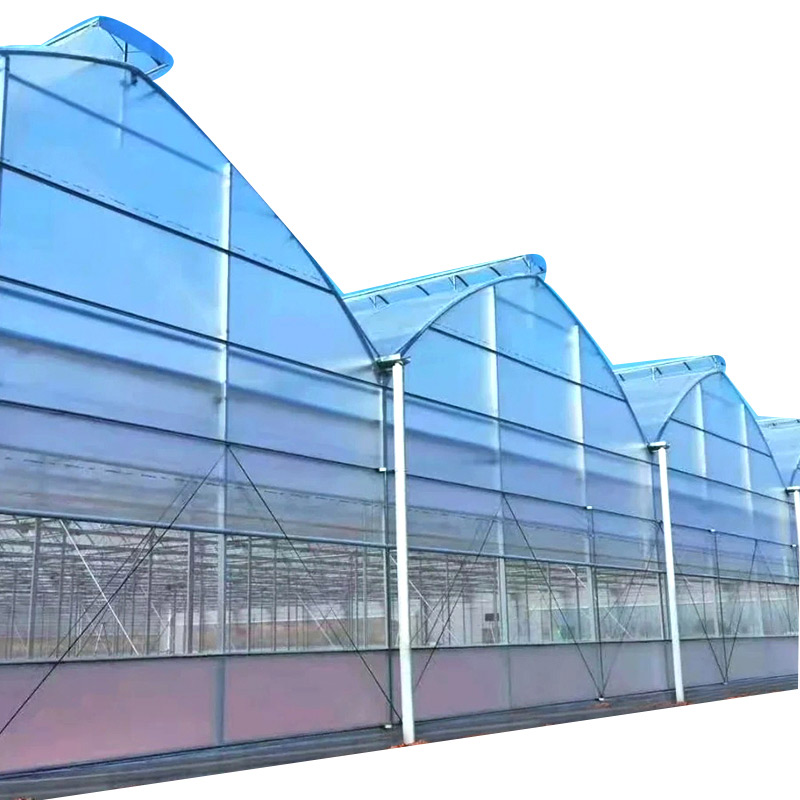

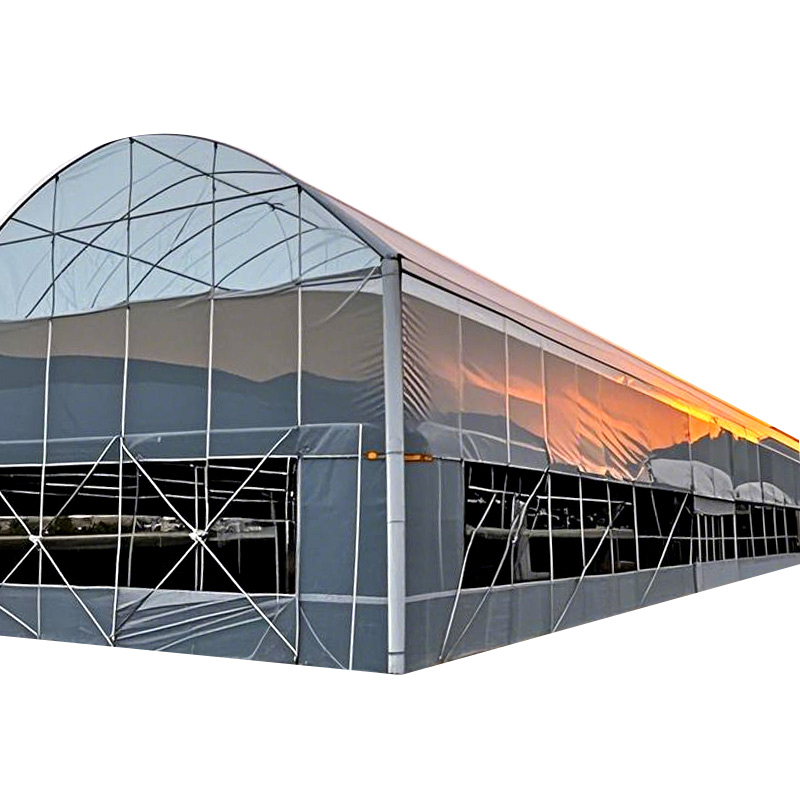

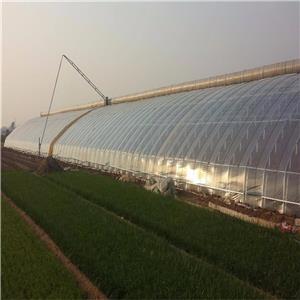

modern film greenhouse,climate controlled film greenhouse and seeding rasing type film greenhouse a cutting-edge agricultural structure that combines high-performance plastic films with smart climate control for year-round crop production. Designed for both commercial growers and research institutions, it offers superior environmental management at a lower cost than traditional glass greenhouses.

Modern Climate Control Dome-shaped Seeding Rasing Film Greenhouse

1. Executive Summary

The modern film greenhouse, climate controlled film greenhouse and seeding rasing type film greenhouse represent a revolutionary approach to seedling production, combining advanced architectural design with precision environmental control systems. This 3000-word technical guide provides an in-depth examination of a structure specifically engineered to optimize the propagation of high-quality seedlings for commercial agriculture, horticulture, and reforestation projects.

This innovative greenhouse system integrates:

Geodesic dome architecture for superior structural performance

Multi-layer specialized film technology for optimal light diffusion

Automated climate control systems for precise environmental management

Energy-efficient design principles for sustainable operation

Smart monitoring technologies for data-driven cultivation

Field tests demonstrate 40-50% faster germination rates and 30-35% stronger seedling development compared to conventional propagation houses, while reducing energy consumption by up to 45%.

2. Architectural Design & Structural Engineering of modern film greenhouse, climate controlled film greenhouse and seeding rasing type film greenhouse

2.1 Geodesic Dome Configuration

Structural Geometry:

3V icosahedron pattern (triangular facets)

Base diameter options: 8m, 12m, 16m

Height-to-diameter ratio: 0.42 (optimal for air circulation)

Load-Bearing Performance:

Snow load capacity: 60kg/m²

Wind resistance: 130km/h (hurricane-force winds)

Seismic stability: 8.0 magnitude earthquake resistant

2.2 Framework Specifications

| Component | Material Specification | Performance Characteristics |

|---|---|---|

| Primary Struts | Aircraft-grade aluminum alloy (6061-T6) | Yield strength: 275MPa |

| Connectors | Hot-dip galvanized steel (Z275 coating) | Corrosion resistance: 25+ years |

| Foundation | Reinforced concrete ring beam | Frost depth penetration: +30cm |

2.3 Space Optimization Features

Vertical Propagation System:

5-tier adjustable growing tables

360° rotating seedling platforms

Automated elevation control

Floor Plan Efficiency:

Central working aisle: 1.2m width

Growing area utilization: 85% of total space

Modular sector division for crop rotation

3. Advanced Film Technology of modern film greenhouse, climate controlled film greenhouse and seeding rasing type film greenhouse

3.1 Multi-layer Composite Film

Layer Construction:

Outer: 0.08mm UV-stabilized PO (5-year warranty)

Middle: 0.03mm EVA light-diffusing layer

Inner: 0.05mm anti-condensation coating

Optical Properties:

PAR transmission: 93% (400-700nm)

Light diffusion: 75% haze

UV-B blocking: 98% (280-315nm)

3.2 Thermal Performance

Insulation Characteristics:

U-value: 2.6 W/(m²·K)

IR retention: 85% (nighttime)

Condensation prevention: surface contact angle >110°

Specialized Features:

Photoselective wavelength filtration

Self-cleaning nanocoatings

Anti-fog additives

4. Climate Control Systems of modern film greenhouse, climate controlled film greenhouse and seeding rasing type film greenhouse

4.1 Temperature Management

Heating Systems:

Underbench hot water pipes (40°C max)

Air-to-air heat recovery ventilation

Phase change material panels (18-22°C range)

Cooling Systems:

Pad-and-fan cooling (30cm cellulose pads)

High-pressure fogging (7μm droplets)

Retractable shade screens (50-90% density)

4.2 Humidity Control

RH Management Range: 65-95% (±3% accuracy)

Systems Integration:

Ultrasonic humidifiers (15L/hr capacity)

Condensate recovery channels

VPD-based automation algorithms

4.3 CO₂ Enrichment

Target Concentration: 800-1200ppm

Delivery Methods:

Compressed gas injection

Combustion generators (propane)

Biological CO₂ production

5. Smart Monitoring & Automation of modern film greenhouse

5.1 Sensor Network

Environmental Sensors:

Air/soil temperature (3-depth profiling)

Leaf wetness detection

PAR intensity (μmol/m²/s)

Substrate EC/pH

System Performance Sensors:

Film surface temperature

Water flow rates

Energy consumption

Remote Management:

Cloud-based monitoring platform

Mobile app alerts

Predictive analytics

6. Seedling Production Optimization of modern film greenhouse

6.1 Propagation Performance

| Crop Type | Germination Rate | Transplant Ready | Survival Rate |

|---|---|---|---|

| Vegetables | 98-99% | 18-25 days | 96% |

| Ornamentals | 95-97% | 30-45 days | 93% |

| Tree Seedlings | 90-92% | 60-90 days | 88% |

6.2 Quality Improvements

Stem Diameter: 25-30% increase

Root Mass: 40-45% greater development

Lignification: 2-3 days faster

Disease Resistance: 50% reduction in damping-off

7. Energy Systems & Sustainability of modern film greenhouse

7.1 Renewable Energy Integration

Photovoltaic System:

Semi-transparent solar panels (25% coverage)

3kW standard capacity

Net-zero energy operation potential

Solar Thermal:

Evacuated tube collectors (200L storage)

Ground-source heat exchange

7.2 Water Management

Conservation Features:

Condensate recovery (85% efficiency)

Closed-loop irrigation

Substrate moisture sensors

8. Operational Protocols of modern film greenhouse

8.1 Sanitation Procedures

Between Crop Cycles:

Steam sterilization (80°C for 60min)

Hydrogen peroxide vapor treatment

Daily Maintenance:

Surface disinfection

Footbath entry systems

Tool sterilization

8.2 Monitoring Schedule

Continuous:

Substrate moisture

CO₂ levels

Light intensity