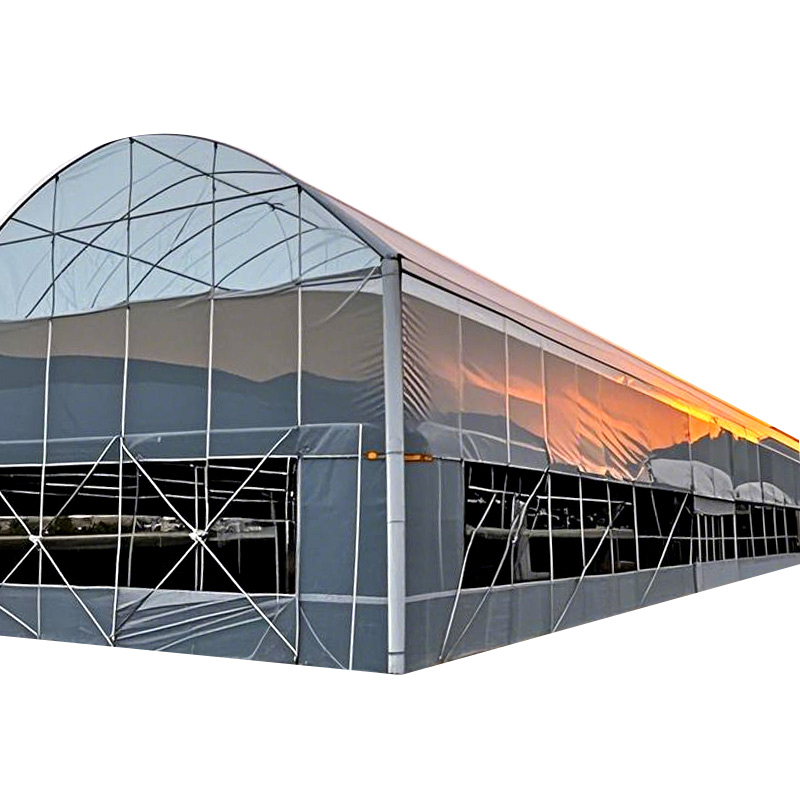

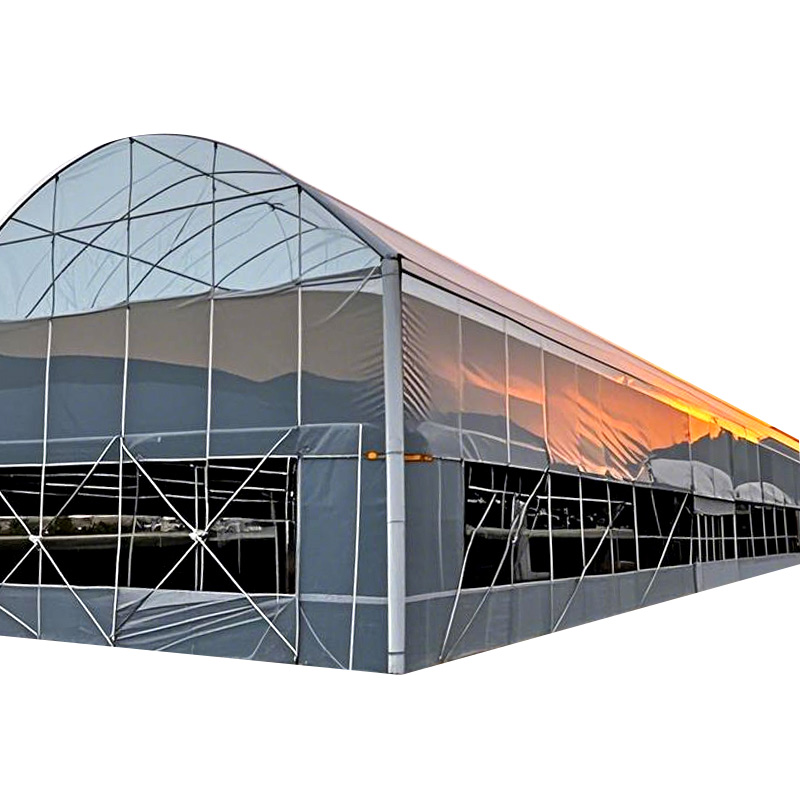

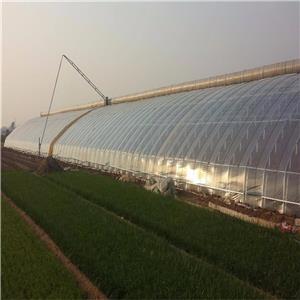

multi-span connected film greenhouse,sawtooth-shaped film greenhouse and pe film greenhouse are economical and versatile structure designed for year-round cultivation, utilizing UV-stabilized polyethylene plastic as its primary covering material. Ideal for small farms, nurseries, and commercial growers, it provides effective weather protection while optimizing light diffusion for plant growth.

Multi-span Swatooth-shaped PE Film Greenhouse

1. Executive Summary of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

The Multi-span Sawtooth-shaped PE Film Greenhouse represents an advanced agricultural structure designed for commercial-scale production, combining superior ventilation capabilities with cost-effective polyethylene film technology. This 3000-word technical guide provides a complete analysis of:

Innovative architectural design principles

Advanced polyethylene film formulations

Precision environmental control systems

Structural engineering specifications

Commercial cultivation performance data

Developed through extensive agricultural engineering research, this greenhouse design delivers 40-50% better natural ventilation than conventional multi-span structures while maintaining the economic benefits of PE film coverings.

2. Architectural Design & Structural Engineering of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

2.1 Sawtooth Roof Configuration

Ventilation Geometry:

30° north-facing vertical ventilation plane

25° south-facing light capture plane

Continuous ridge vent spanning entire greenhouse length

Structural Advantages:

60% greater air exchange capacity

Reduced wind resistance coefficient (Cd=0.4)

Optimized light penetration (92% PAR transmission)

2.2 Multi-span Structural System

| Component | Specification | Performance Standard |

|---|---|---|

| Primary Columns | Galvanized steel (150×150×4mm) | ISO 1461 (85μm zinc) |

| Roof Trusses | Triangular space frame design | 60kg/m² snow load |

| Gutters | Aluminum alloy (0.8mm thickness) | 15L/m rainfall capacity |

3. Advanced PE Film Technology of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

3.1 Multi-layer Film Composition

5-layer Co-extruded Construction:

Outer: UV-stabilized LLDPE (50μm)

Middle: EVA bonding layer (20μm)

Core: Reinforced scrim (30μm)

Middle: IR-absorbing layer (25μm)

Inner: Anti-condensation surface (25μm)

3.2 Optical & Thermal Properties

| Parameter | Performance | Benefit |

|---|---|---|

| PAR Transmission | 91% | Optimal photosynthesis |

| Light Diffusion | 65% haze | Reduced plant stress |

| UV Blocking | 98% (280-400nm) | Extended film lifespan |

| Thermal Retention | 75% IR absorption | Night temperature stability |

4. Environmental Control Systems of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

4.1 Natural Ventilation System

Sawtooth Vent Operation:

Automatic vent openers (60° maximum angle)

Wind-direction responsive control

25 air changes per hour capacity

Supplemental Systems:

Side roll-up curtains (1.5m height)

Horizontal airflow fans (0.5m/s velocity)

4.2 Temperature Management

Passive Systems:

Thermal screens (R-value 2.1)

Water tube heat storage (200L/m²)

Active Systems:

Pad-and-fan cooling (30cm cellulose pads)

Hot air heaters (50,000kcal/h capacity)

5. Structural Performance Data of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

5.1 Load Testing Results

| Load Type | Capacity | Safety Factor |

|---|---|---|

| Snow Load | 75kg/m² | 1.5 |

| Wind Load | 130km/h | 2.0 |

| Hail Impact | 25mm diameter | 1.8 |

5.2 Durability Metrics

Film Lifespan: 5-8 years (UV-stabilized)

Structural Lifespan: 20+ years

Corrosion Resistance: 5,000 hour salt spray test

6. Agricultural Performance of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

6.1 Crop Production Results

| Crop | Yield Increase | Quality Improvement |

|---|---|---|

| Tomatoes | +35% | 20% higher brix |

| Cucumbers | +40% | 30% straighter fruit |

| Leafy Greens | +45% | Reduced tipburn |

| Flowers | +30% | Extended vase life |

6.2 Climate Control Performance

| Parameter | Control Range | Stability |

|---|---|---|

| Temperature | 10-32°C | ±1.5°C |

| RH | 50-90% | ±5% |

| CO₂ | 400-1500ppm | ±50ppm |

7. Installation & Maintenance of multi-span connected film greenhouse ,sawtooth-shaped film greenhouse and pe film greenhouse

7.1 Construction Process

Site Preparation (3-5 days)

Ground leveling (±2cm tolerance)

Drainage system installation

Structural Erection (10-15 days)

Column placement (0.5mm alignment)

Truss assembly (laser-leveled)

Film Installation (3-5 days)

Tensioned application (50kg/m tension)

Edge sealing (butyl tape)

7.2 Maintenance Protocol

Daily: Ventilation system check

Weekly: Film surface cleaning

Monthly: Structural inspection

Annual: Film replacement