A-shaped hydroponic planting system is an efficient vertical farming design that maximizes growing space while minimizing footprint. Its triangular structure provides dual-sided planting surfaces, making it ideal for leafy greens, herbs, and strawberries.

A-shaped Hydroponic Planting System

1. Introduction to A-shaped hydroponic planting system

The A-Frame hydroponic system represents a revolutionary approach to vertical farming, combining space efficiency with high-yield production. Characterized by its distinctive triangular structure, this design provides dual growing surfaces at optimal angles for light penetration and easy harvesting. Originally developed for commercial lettuce production, A-Frame systems now accommodate everything from strawberries to medicinal herbs.

Why Choose A-shaped hydroponic planting system?

Space Optimization: Grows 2-3x more plants per square foot than flat beds

Ergonomic Design: 45-60° angle reduces labor strain during maintenance

Adaptability: Functions with NFT, drip irrigation, or aeroponic systems

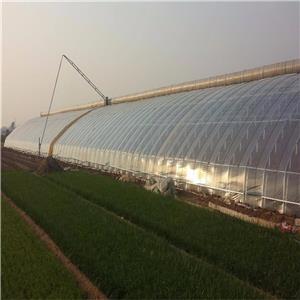

Climate Resilience: Protected growing environment for year-round production

2. Historical Development of A-shaped hydroponic planting system

1970s: Early prototypes emerge in Dutch greenhouse operations

1990s: Commercial adoption for lettuce in Japan and California

2010s: Integration with LED lighting and automation technologies

Present: Standard in urban vertical farms and research facilities

3. Scientific Principles of A-shaped hydroponic planting system

The A-Frame's effectiveness stems from three core scientific advantages:

Light Penetration

The 45-60° angle ensures:92% light absorption efficiency (vs 68% in flat beds)

Even distribution across all plant levels

Reduced shading between plants

Gravity-Assisted Drainage

Natural water flow prevents stagnation

30% less pump energy required than vertical towers

Microclimate Control

Air circulates freely through open center

Temperature variance <2°C across structure

4. System Components

| Component | Purpose | Recommended Specifications |

|---|---|---|

| Frame Structure | Structural support | Powder-coated aluminum or UV-resistant PVC |

| Growing Channels | Plant housing | Food-grade PVC pipes (3-6" diameter) or gutters |

| Irrigation System | Nutrient delivery | Drip emitters (0.5 GPH) or NFT channels |

| Reservoir | Nutrient storage | 20-100 gallon capacity |

| Water Pump | Circulation | 400-800 GPH submersible |

| Lighting System | Supplemental light | Full-spectrum LEDs (50W per linear foot) |

5. Types of A-Frame Systems

A. NFT (Nutrient Film Technique) A-Frames

Best for: Leafy greens, herbs

Flow rate: 1-2 liters per minute

Advantage: Minimal media needed

B. Drip Irrigation A-Frames

Best for: Strawberries, peppers

Media: Coco coir or perlite

Advantage: Precise nutrient control

C. Hybrid Aeroponic A-Frames

Best for: High-value crops

Technology: Root misting every 3-5 minutes

Advantage: 40% faster growth rates

6. Growing Media Comparison

| Media Type | A-Frame Suitability | Pros | Cons |

|---|---|---|---|

| Clay Pebbles | Excellent | Reusable, good drainage | Heavy when wet |

| Coconut Coir | Good | Sustainable, moisture-retentive | Requires buffering |

| Rockwool | Fair | Sterile, consistent | Non-biodegradable |

| Perlite | Good | Lightweight, inexpensive | Can compact over time |

7. Plant Selection Guidelines

Top Performing Crops:

Leafy Greens: Lettuce (all varieties), kale, arugula

Herbs: Basil, cilantro, mint

Fruiting Plants: Strawberries, cherry tomatoes

Flowers: Petunias, marigolds (for companion planting)

Plants to Avoid:

Large root vegetables (carrots, potatoes)

Vining plants (unless pruned aggressively)

Tall crops (corn, sunflowers)

8. Lighting Strategies

Natural Light Optimization

Orient frames north-south for even sun exposure

6+ hours direct sunlight required outdoors

Artificial Lighting Solutions

LED Strip Configuration: 30W per linear foot

Light Schedule: 14-16 hours daily for greens

PAR Requirements: 200-400 μmol/m²/s for vegetative growth

9. Structural Engineering

Critical Design Parameters:

Angle: 50° optimal for light/water distribution

Base Width: 24-36 inches for stability

Height: 6-8 feet maximum for easy access

Load Capacity: 5 lbs per linear foot (when wet)

Material Options:

PVC: Affordable (1.50 per linear foot)

Aluminum: Durable (5 per linear foot)

Stainless Steel: Commercial-grade ($8+ per linear foot)

10. Step-by-Step Construction

Materials Needed:

(4) 8' 2x4 lumber or PVC pipes

(2) 4' crossbeams

10' of 4" PVC gutter

400 GPH water pump

20-gallon reservoir

Assembly Instructions:

Construct A-frame with 50° angle using metal brackets

Install growing channels at 12" vertical spacing

Connect irrigation lines with 6" emitter spacing

Test water flow (adjust slope as needed)

Install plants in net pots with media