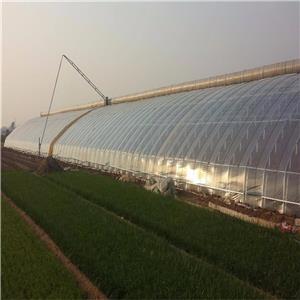

Heat-Preservation Glass Greenhouse is an advanced agricultural structure designed to minimize heat loss and maximize energy efficiency, making it ideal for cold climates, winter cultivation, and high-value crop production. By incorporating insulating glass, thermal screens, and intelligent climate control, this greenhouse maintains stable temperatures even in sub-zero conditions, ensuring uninterrupted plant growth and higher yields while reducing heating costs.

Heat-Preservation Venlo-Type Greenhouse combines the proven Dutch Venlo design with next-generation thermal insulation technologies, creating an ultra-efficient growing environment for cold climates and winter cultivation. Its multi-span glass structure, energy-retention systems, and smart climate control ensure minimal heat loss, reduced energy costs, and stable crop production even in sub-zero temperatures.

Introduction to Heat-preservation Venlo Technology

1 Evolution of heat-preservation glass greenhouse and heat-preservationVenlo-type greenhouse Design

Heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse represent a revolutionary advancement in protected agriculture, originating from the traditional Dutch Venlo design that emerged in the 1950s. This modern iteration specifically addresses the critical challenge of energy efficiency in temperate and cold climate zones through:Double-layer insulated glazing systems,Advanced thermal screen technologies,Intelligent climate control integration,Structural enhancements for extreme weather resistance Core Value Propositions.

heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse deliver:55-65% reduction in heating energy consumption compared to single-glazed structures,Year-round production capability even in sub-zero conditions,

90%+ light transmission maintaining photosynthetic efficiency,25-30 year lifespan with proper maintenance,15-25% yield increases through climate optimization.

2. Framing System Specifications of heat-preservation greenhouse and heat-preservation Venlo-type glass greenhouse

| Component | Technical Specification | Performance Benefit |

|---|---|---|

| Primary Structure | Aluminum alloy (6063-T5) | Corrosion resistance |

| Secondary Supports | Hot-dip galvanized steel | Structural integrity |

| Span Configuration | 8-12m clear spans | Unobstructed growing |

| Snow Load Capacity | 75kg/m² (minimum) | Nordic climate suitability |

| Wind Resistance | 130km/h certified | Storm protection |

Glazing Innovations:The 4-5mm tempered glass panels feature:Low-iron composition (91-94% PAR transmission),Anti-reflective coatings (up to 97% light capture),Hydrophilic surface treatment for condensation control,16-24mm argon-filled cavities in double-glazed units,Optional triple glazing for extreme climates (U-value 1.6W/m²K).

3.Heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse have

Multi-Layer Insulation Strategy:Primary Barrier: Insulated glazing units,Secondary Barrier: Retractable thermal screens,Tertiary Barrier: Perimeter weather seals,Quaternary Barrier (optional): Underground heat storage.Energy Performance Metrics,Annual heating demand: 80-150kWh/m² (temperate zones)

Temperature stability: ±1.5°C diurnal fluctuation,Heat loss reduction: 50-70% versus conventional designs

Solar heat capture: 65-75% of incident radiation utilizedClimate Control Integration,Automated screen systems with light-diffusing fabrics,Underbench hydronic heating (40-45°C water temperature),Heat recovery ventilators (75% efficiency)

Condensation prevention via roof vent algorithms

4. Vegetable Cultivation Performance of heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse

| Crop | Annual Yield | Energy Use | Premium Quality Factors |

|---|---|---|---|

| Tomatoes | 70-90kg/m² | 110kWh/m² | Brix levels 8.5-9.5 |

| Cucumbers | 120-150 fruits/m² | 95kWh/m² | Straightness >95% |

| Peppers | 25-35kg/m² | 105kWh/m² | Wall thickness 6-8mm |

| Leafy Greens | 12-15 cuts/yr | 75kWh/m² | Nitrate content <2000ppm |

heat-preservation glass greenhouse and heat-preservation Venlo-type greenhousehave Specialized Production Systems,Vertical growing (3-5x area utilization),Aquaponic integration (closed-loop systems),

Pharmaceutical-grade herbs (climate traceability),Micropropagation (disease-free plantlets)。

5.

heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse have Capital Expenditure Breakdown,Structure & glazing: €120-180/m²Climate systems: €60-100/m²Automation: €40-80/m²

Ancillary systems: €20-40/m²Total installed cost: €240-400/m²Operational EconomicsEnergy savings: €15-25/m² annuallyLabor efficiency: 30% reductionYield premiums: 20-35% market valuePayback period: 5-7 years.

Lifecycle Cost Comparison of heat-preservation glass greenhouse and heat-preservation Venlo-type greenhouse

| Metric | Heat-preservation Venlo | Traditional Venlo | Poly Tunnel |

|---|---|---|---|

| 10yr Energy Cost | €180/m² | €320/m² | €400/m² |

| Structure Lifetime | 25-30yrs | 15-20yrs | 5-8yrs |

| Annual Maintenance | 1.5% | 2.5% | 4% |

| Total Cost of Ownership | €580/m² | €720/m² | €650/m² |

heat-preservation Venlo-type greenhouse represents not just an agricultural tool, but a strategic investment in food security as climate volatility increases. Our engineering team stands ready to assist with custom feasibility studies and turnkey project development tailored to your specific crop and climate requirements.