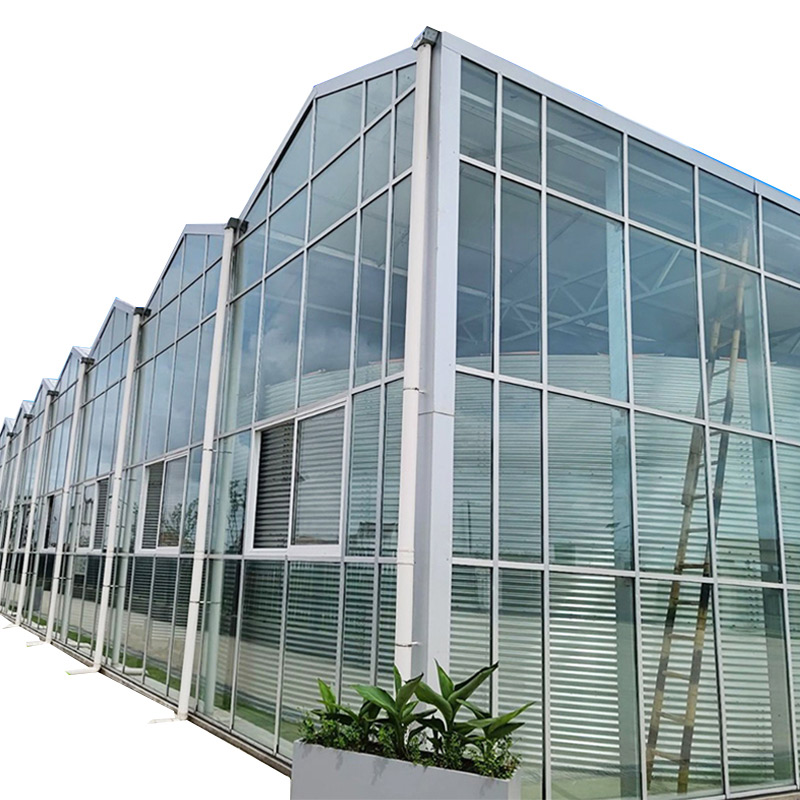

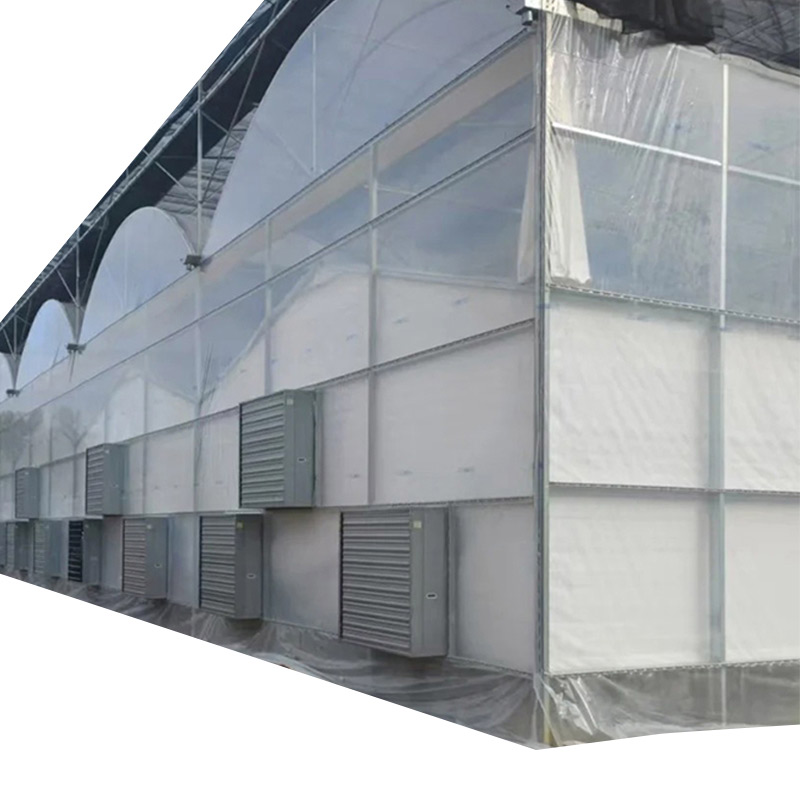

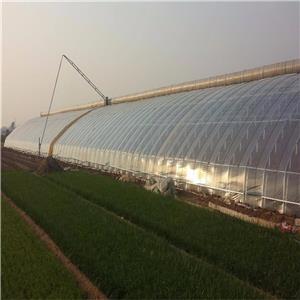

Compact Polycarbonate Greenhouse is Ideal for urban gardens and hobbyists, this small greenhouse features 4mm twin-wall polycarbonate panels offering: 85% light transmission with UV protection,R1.7 insulation for season extension, Durable aluminum frame (5'x8' to 8'x12' sizes), Easy assembly with sliding door access.Multi-Span Polycarbonate Greenhouse, ecological polycarbonate plate greenhouse and seeding rasing polycarbonate plate greenhouse are designed for commercial growers, this high-capacity greenhouse features connected arched bays with 8-16mm multi-wall polycarbonate panels delivering: 90% light transmission with anti-condensation layers, Ultra-efficient climate control (integrated ventilation/heating channels), Industrial-strength frame (snow load 40kg/m², wind resistance 120km/h).

Small Seeding Rasing Muti-span Polycarbonate Greenhouse

1. Introduction to small polycarbonate greenhouse,multi-span polycarbonate greenhouse,seeding rasing polycarbonate plate greenhouse and ecological polycarbonate plate greenhouse

Small seedling raising demands precision-controlled environments where temperature stability, uniform light distribution, and humidity control are critical. Multi-span polycarbonate greenhouses provide the ideal solution by combining:

✔ Microclimate zones for different growth stages

✔ Energy-efficient insulation (R-values up to 2.5)

✔ Modular scalability from 500m² to 5,000m²

✔ 98%+ germination rates under optimized conditions

These structures are revolutionizing commercial nurseries, vegetable transplant production, and reforestation programs worldwide.

2. Why Polycarbonate for small polycarbonate greenhouse,multi-span polycarbonate greenhouse,seeding rasing polycarbonate plate greenhouse and ecological polycarbonate plate greenhouse?

Material Advantages:

| Property | Benefit for Seedlings |

|---|---|

| 90% light transmission | Prevents leggy growth |

| UV protection | Reduces transplant shock |

| Diffused light | Eliminates leaf burn |

| Condensation control | Prevents damping-off disease |

Comparative Performance ofsmall polycarbonate greenhouse,multi-span polycarbonate greenhouse,seeding rasing polycarbonate plate greenhouse and ecological polycarbonate plate greenhouse

| Material | Light Diffusion | Insulation (R-value) | Durability |

|---|---|---|---|

| Polycarbonate | Excellent (20-30% haze) | 1.7-2.5 | 15-20 years |

| Glass | Poor (0% haze) | 0.9 | Fragile |

| Polyethylene | Good (40% haze) | 0.7 | 2-3 years |

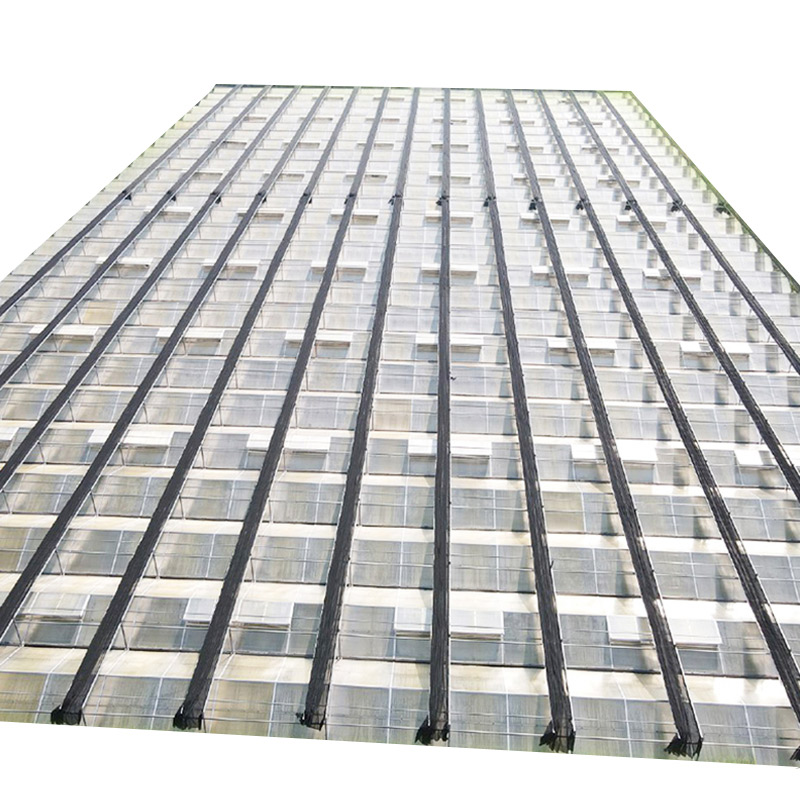

3. Multi-Span Structural Advantages

Key Features:

Gutter-connected design maximizes space (85% usable area vs 70% in single-span)

Column-free interiors for flexible benching layouts

Snow load capacity up to 45kg/m² (triple-wall panels)

Wind resistance to 130km/h

Span Configurations:

| Span Width | Recommended Use |

|---|---|

| 3.2m | Compact seedling trays |

| 4.0m | Mechanized transplant lines |

| 5.0m | Tall propagation stock |

4. Light Transmission Optimization

Ideal PAR Levels:

Germination: 100-200 μmol/m²/s

Early growth: 200-400 μmol/m²/s

Hardening-off: 400-600 μmol/m²/s

Panel Selection Guide:

| Panel Type | Light Transmission | Best Growth Stage |

|---|---|---|

| 4mm twin-wall | 88% | Germination |

| 6mm triple-wall | 86% | Vegetative growth |

| 10mm X-structure | 84% | Cold climate hardening |

5. Climate Control Systems of small polycarbonate greenhouse

Temperature Management:

Heating: Under-bench hot water pipes (40°C max)

Cooling: Pad-and-fan systems (Δ5°C achievable)

Thermal screens: Energy savings up to 60%

Humidity Control:

Fogging systems maintain 70-85% RH

Dehumidifiers prevent fungal outbreaks

6. Ventilation Design of small polycarbonate greenhouse

Roof vents (20% of floor area)

Sidewall louvers with insect screens

Continuous ridge ventilation

7. Irrigation Technology of small polycarbonate greenhouse

| System Type | Application |

|---|---|

| Overhead misting | Germination |

| Boom irrigation | Young seedlings |

| Ebb-and-flow | Plug trays |

8. Heating Solutions

Biomass boilers (most economical)

Heat pumps (precise ±0.5°C control)

Solar thermal storage

9. Space Optimization

Benching Layouts:

Rolling benches (90% space utilization)

Multi-tier systems (3x capacity)

Mobile tray carts

10. Disease Prevention

Positive pressure ventilation

Copper-infused polycarbonate

UV-C sterilization zones

11. Automation Features

Climate computers with crop algorithms

IoT soil moisture sensors

Automatic shade adjustment

12. Energy Efficiency

Insulation: R-2.5 panels reduce heat loss

LED supplementation: 50% less power than HPS

Heat recovery ventilators

13. Crop-Specific Adaptations

Vegetable Plugs:

Day/night ΔT <5°C

16h photoperiod

Forestry Seedlings:

Far-red light for stem thickening

Wind simulation systems

14. Construction Details

Foundation: Ground screws (no concrete)

Glazing: Thermal-break gaskets

Snow load: Reinforced purlins

15. Operational Protocols

Daily: Check misting nozzles

Weekly: Disinfect surfaces

Monthly: Calibrate sensors

16. Cost Analysis

| Size | Cost/m² | ROI Period |

|---|---|---|

| 500m² | $85 | 2.8 years |

| 1,000m² | $72 | 2.1 years |

| 2,000m² | $65 | 1.7 years |

17. Case Studies

Dutch Tomato Nursery:

1.2ha multi-span

15M seedlings/year

30% energy savings

18. Maintenance

Annual: Panel optical testing

5-year: Structure realignment

19. Future Tech

Self-cleaning nanocoatings

AI disease prediction

20. Troubleshooting

Issue: Uneven growth

Solution: Adjust light diffusion

21. FAQs

Q: Minimum height for seedlings?

A: 3.5m for air stratification

22. Conclusion

Multi-span polycarbonate greenhouses provide the perfect controlled environment for high-value seedling production with unmatched efficiency and yield consistency.