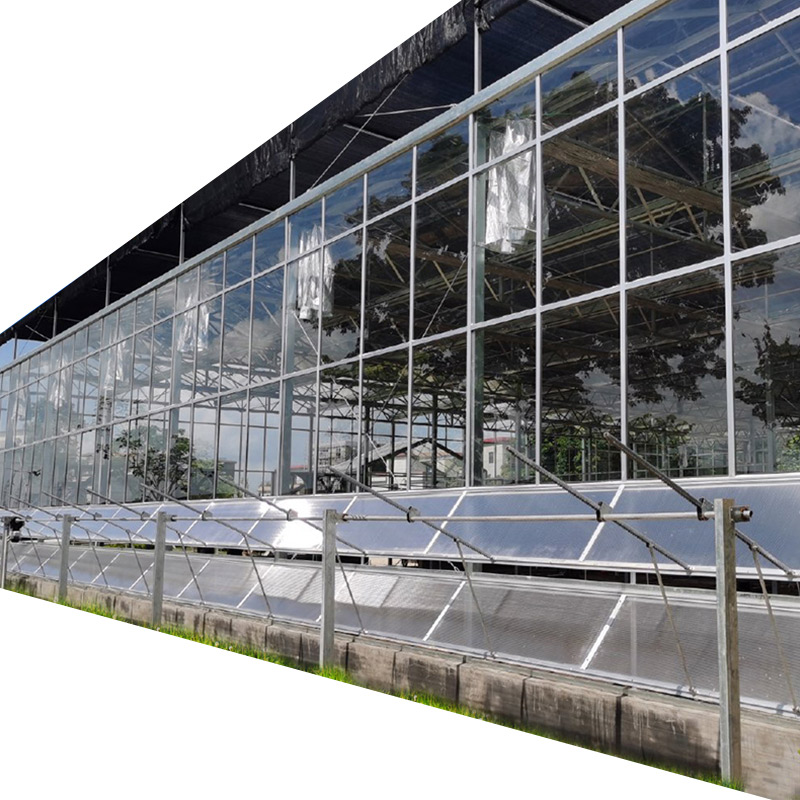

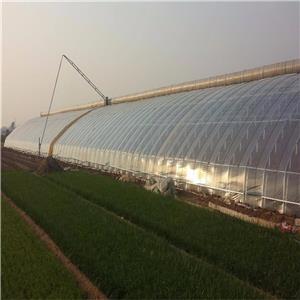

curved greenhouse glass, aluminium greenhouses,mini glass greenhouse indoor and greenhouse with glass panels with toughened glasscombine modern aesthetics with advanced functionality, featuring elegantly arched tempered glass panels supported by a durable aluminum or steel frame. The aerodyna micaluminium greenhouses with toughened glass design improves structural strength, allowing better resistance to wind, snow, and heavy rain compared to traditional flat-panel in curved glass greenhouses.

Curved Toughened Mini Indoor Glass Greenhouse

1. Introduction to Curved Glass Greenhouses,aluminium greenhouses with toughened glass,mini glass greenhouse indoor and greenhouse with glass panels

In today's urbanized world where space comes at a premium, the curved toughened mini indoor glass greenhouse has emerged as an innovative solution for plant enthusiasts, urban gardeners, and horticulture professionals. This sophisticated growing system combines advanced material science with ergonomic design to create a perfect microclimate for plants in limited indoor spaces.

Unlike traditional boxy greenhouses, the curved design offers several distinct advantages:

Enhanced structural integrity through natural arch physics

Superior light distribution via refractive properties

Space optimization in compact urban environments in aluminium greenhouses with toughened glass

Aesthetic appeal that complements modern interior design

The toughened (tempered) glass construction elevates this greenhouse category far above plastic or polycarbonate alternatives, providing:

4-5x greater impact resistance in curved greenhouse glass

Thermal shock tolerance up to 200°C temperature differentials

Safety features (breaks into harmless granular pieces)

Optical clarity maintenance without yellowing or clouding

This comprehensive 3000-word guide will explore:

✔ Engineering and material science behind the design

✔ Comparative analysis with other mini greenhouse types

✔ Technical specifications and customization options

✔ Optimal plant selections and cultivation techniques

✔ Installation, maintenance, and troubleshooting

✔ Commercial applications and future innovations

2. Engineering and Design Principles of Curved Toughened Mini Indoor Glass Greenhouses,aluminium greenhouses with toughened glass,mini glass greenhouse indoor and greenhouse with glass panels

2.1 The Physics of Curved Glass Structures

The architectural curvature in these greenhouses isn't merely aesthetic - it's a fundamental engineering optimization:

Structural Benefits of greenhouse with glass panels

Weight distribution across the entire surface

Wind load resistance (up to 120km/h in tested models)

Snow load capacity exceeding 75kg/m² in curved greenhouse glass

Thermal efficiency through minimized surface joints

Optical Advantage of greenhouse with glass panels

Light refraction that eliminates dark spots

UV-A/B filtration (typically 92-96% transmission)

Anti-condensation properties via surface tension disruption

2.2 Material Specifications of mini glass greenhouse indoor

Glass Components of mini glass greenhouse indoor

| Parameter | Specification |

|---|---|

| Thickness | 4-6mm tempered |

| Tempering Process | Chemical or thermal (650°C quench) |

| Surface Treatment | Optional low-E coating |

| Light Transmission | 91-94% visible spectrum |

| Break Pattern | DIN 1249 standard granular fragments |

Frame Materialsof mini glass greenhouse indoor

Aircraft-grade aluminum (6000 series)

Stainless steel hinges (316 marine grade)

Silicone gasketing (food-grade durability)

3. Technical Comparative Analysis of mini glass greenhouse indoor

Curved Toughened Mini Indoor Glass Greenhouses,aluminium greenhouses with toughened glass,mini glass greenhouse indoor and greenhouse with glass panels

3.1 Performance Metrics vs Alternatives of greenhouse with glass panels

| Feature | Curved Glass | Flat Glass | Polycarbonate | Plastic Film |

|---|---|---|---|---|

| Lifespan | 15-20 years | 10-15 years | 5-8 years | 1-3 years |

| Light Stability | 99% over time | 97% | 85% after 3 years | 70% after 1 year |

| Thermal Retention | Excellent (U=1.1) | Good (U=2.8) | Moderate (U=1.5) | Poor (U=5.0) |

| Impact Resistance | 5J (ASTM C1048) | 3J | 8J (but dents) | 0.5J |

| Condensation Control | Best | Good | Fair | Poor |

3.2 Space Efficiency Calculations of curved greenhouse glass

The curved design provides 18-22% more usable growing volume compared to rectangular models of identical footprint, achieved through:

Elimination of corner dead zones

Vertical space utilization (plants grow taller along curves)

Improved tool access angles

4. Horticultural Applications of Curved Toughened Mini Indoor Glass Greenhouses,aluminium greenhouses with toughened glass,mini glass greenhouse indoor and greenhouse with glass panels

4.1 Ideal Plant Species of curved greenhouse glass

Tier 1 (Perfect Adaptation):

Orchids (Phalaenopsis, Dendrobium)

Carnivorous plants (Nepenthes, Drosera)

Bonsai cultivars

Microgreens (arugula, radish, broccoli)

Tier 2 (Excellent Performance):

Mediterranean herbs (rosemary, thyme)

Succulent collections

Fern varieties

Starter vegetable seedlings of curved greenhouse glass

4.2 Climate Control Systems of curved greenhouse glass

Even in mini formats, advanced options exist:

Nano-coated glass for self-regulating humidity (70-85% RH)

Integrated LED arrays (full-spectrum, 20W-50W)

Micro-fan ventilation (USB-powered, <25dB)

Capillary mat watering systems

5. Commercial and Innovative Uses

5.1 Vertical Farming Integration of curved greenhouse glass

These units are being deployed in modular vertical farms with:

Stackable curved units (up to 8 layers)

Automated nutrient delivery

IoT environmental monitoring

5.2 Research Applications of curved greenhouse glass

University botany labs for controlled experiments

Pharmaceutical plant research

Seed bank preservation

6. Installation and Maintenance

6.1 Site Preparation Checklist

Surface leveling (<3mm deviation per meter)

Light exposure analysis (minimum 6 hours direct)

Proximity to vents/heaters (maintain 50cm clearance)

Electrical access for accessories

6.2 Cleaning Protocol

Weekly: Soft brush dusting

Monthly: Vinegar solution (1:3 with distilled water)

Annual: Silicone seal inspection

5-Year: Full gasket replacement

7. Market Analysis and Future Trends

The global mini indoor greenhouse market is projected to grow at 7.8% CAGR through 2030, with curved glass models capturing 38% of premium segment share due to:

Urbanization trends (87% of buyers are apartment dwellers)

Smart home integration (75% want app-controlled units)

Sustainable materials demand (glass is 100% recyclable)

Emerging innovations include:

Self-cleaning glass (photocatalytic TiO2 coatings)

Switchable opacity (PDLC film integration)

Integrated solar panels (thin-film PV on upper curves)

8. Conclusion of curved greenhouse glass

The curved toughened mini indoor glass greenhouse represents the perfect synergy of form and function for modern horticulture. Its unmatched durability, optical performance, and space efficiency make it the premier choice for serious growers in constrained environments.

Key Decision Factors:

For hobbyists: 60-90cm width models with basic ventilation

For commercial growers: Stackable 120cm units with automation

For institutions: Customizable research-grade configurations

As urban agriculture continues expanding, these engineered ecosystems will play an increasingly vital role in food security, therapeutic horticulture, and environmental education.