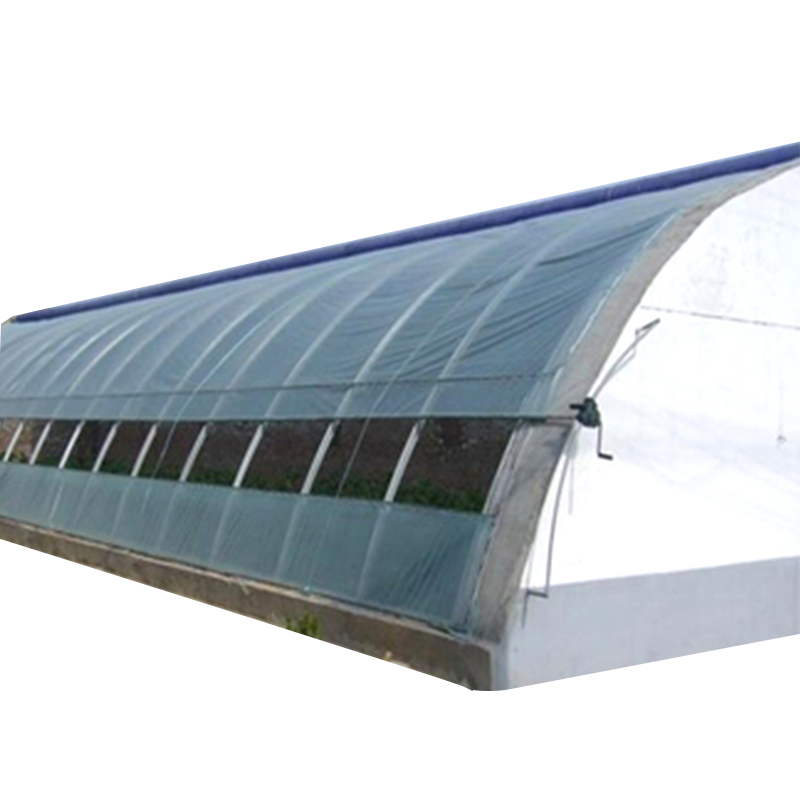

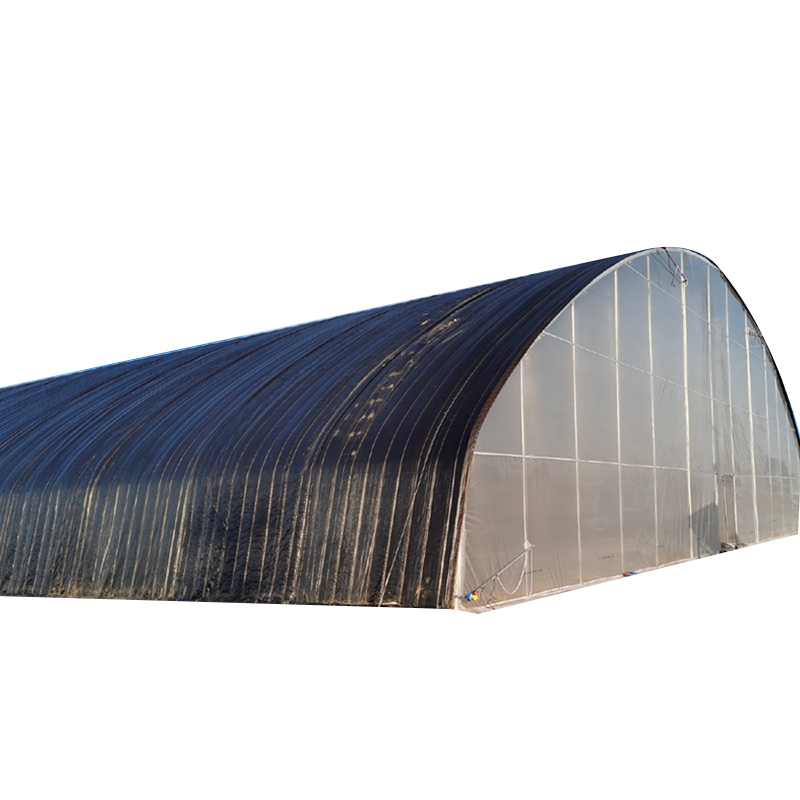

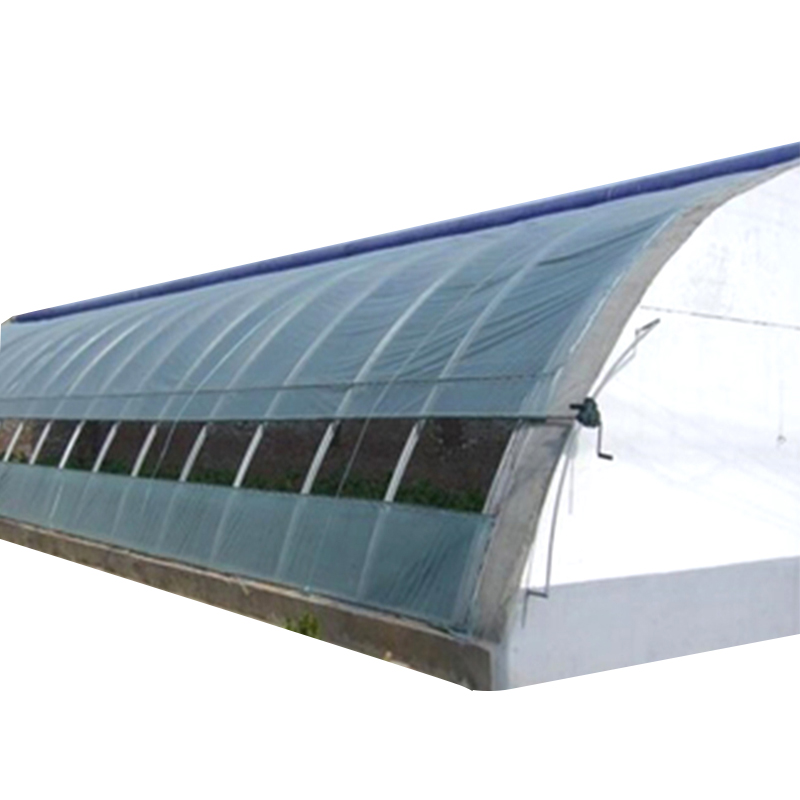

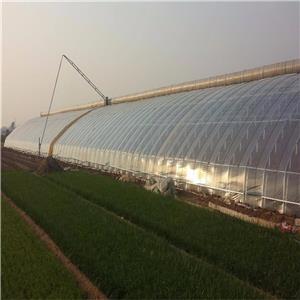

high load solar greenhouse,hot-dip galvanized steel pipe framework solar greenhouse and ventilated solar greenhouse are ultra-durable structure engineered to withstand extreme weather while optimizing solar energy for year-round cultivation. Featuring a reinforced steel/aluminum frame and impact-resistant polycarbonate panels, it survives heavy snow (50+ lbs/sqft), strong winds (100+ mph), and hail.

High Load Hot-dip Galvanized Steel Pipe Framework Solar Greenhouse

1. Introduction of high load solar greenhouse and ventilated solar greenhouse

The High Load Hot-Dip Galvanized Steel Pipe Framework Solar Greenhouse represents the pinnacle of agricultural infrastructure engineering, combining industrial-grade structural integrity with advanced solar energy utilization. Designed for commercial-scale operations and extreme climate conditions, this greenhouse system delivers unmatched durability, energy efficiency, and productivity through its innovative design and premium materials.

This comprehensive technical dossier examines:

Structural engineering specifications

Material science breakthroughs

Thermal performance characteristics

Comparative advantages over conventional structures

Commercial implementation case studies

2. Structural Engineering Excellence of high load solar greenhouse and ventilated solar greenhouse

2.1 Hot-Dip Galvanized Steel Framework

Material Specifications:

ASTM A123-certified galvanized steel pipes

2.5mm minimum wall thickness

150-200μm zinc coating (standard) or 300μm (arctic/coastal variants)

Structural Performance:

Snow load capacity: 75kg/m² (157lbs/ft²)

Wind resistance: 130km/h (81mph) sustained winds

Seismic rating: 8.0 magnitude earthquake resistant

2.2 Optimized Truss Design

Triangular space frame architecture reduces material weight by 25% while increasing rigidity

Modular connection system allows span widths up to 16m (52ft) without internal supports

Adjustable roof pitch (25°-35°) optimized for solar gain at different latitudes

3. Advanced Cladding Systems of high load solar greenhouse and ventilated solar greenhouse

3.1 Solar-Optimized Glazing

Twin-wall polycarbonate panels:

16mm thickness with UV-blocking treatment

88% light transmission with anti-condensation layer

R-value of 2.04 (m²·K)/W

Optional photovoltaic integration:

Semi-transparent solar panels (30% light transmission)

175W/m² power generation capacity

3.2 Thermal Management

Automated insulation systems:

Retractable thermal screens (R-value 3.5)

Phase-change material panels in north wall

Ground-to-air heat exchange:

40cm diameter buried pipes (3m depth)

75% heat recovery efficiency

4. Performance Metrics of high load solar greenhouse and ventilated solar greenhouse

| Parameter | Performance | Industry Standard |

|---|---|---|

| Structural lifespan | 30+ years | 10-15 years |

| Annual energy savings | 85% vs conventional | 30-50% |

| Temperature stability | ±2°C diurnal variation | ±5-8°C |

| Light utilization | 92% PAR efficiency | 70-80% |

| Maintenance cost | $0.15/sqft/year | $0.50-0.75 |

5. Commercial Applications of high load solar greenhouse and ventilated solar greenhouse

5.1 Extreme Climate Adaptations

Alpine version: Withstands 2m snow accumulation

Desert version: Integrated evaporative cooling

Coastal version: 316L stainless steel hardware

5.2 Specialty Crop Systems

Vertical hydroponics integration

Automated shading systems for medicinal plants

CO₂ enrichment systems for high-value crops

6. Installation & Maintenance

6.1 Foundation Options

Concrete piers: 80cm depth (standard)

Ground screws: For temporary installations

Radial drainage system: Prevents frost heave

6.2 Robotic Maintenance Features

Automated panel cleaning drones

Structural health monitoring sensors

Predictive maintenance algorithms

7. Economic Analysis

| Investment Aspect | Value Proposition |

|---|---|

| Capital cost | $38-55/sqft |

| ROI period | 2.8 years (strawberries) |

| Insurance premium | 30% lower than standard |

| Depreciation | 20-year schedule |

8. Future Development Roadmap

AI-powered structural optimization

Self-healing polymer coatings

Integrated water harvesting

9. Conclusion

This engineering masterpiece redefines greenhouse performance through:

Military-grade structural reliability

Closed-loop energy systems

Smart automation integration