Compact solar greenhouse,single-span solar greenhouse and arch-shaped solar greenhouse have key energy-saving features include:Semi-transparent photovoltaic panels generating 175W/m,Ground-source heat exchange system with 75% efficiency,Smart climate control reducing heating costs by 85%,Rainwater harvesting and drip irrigation systems。

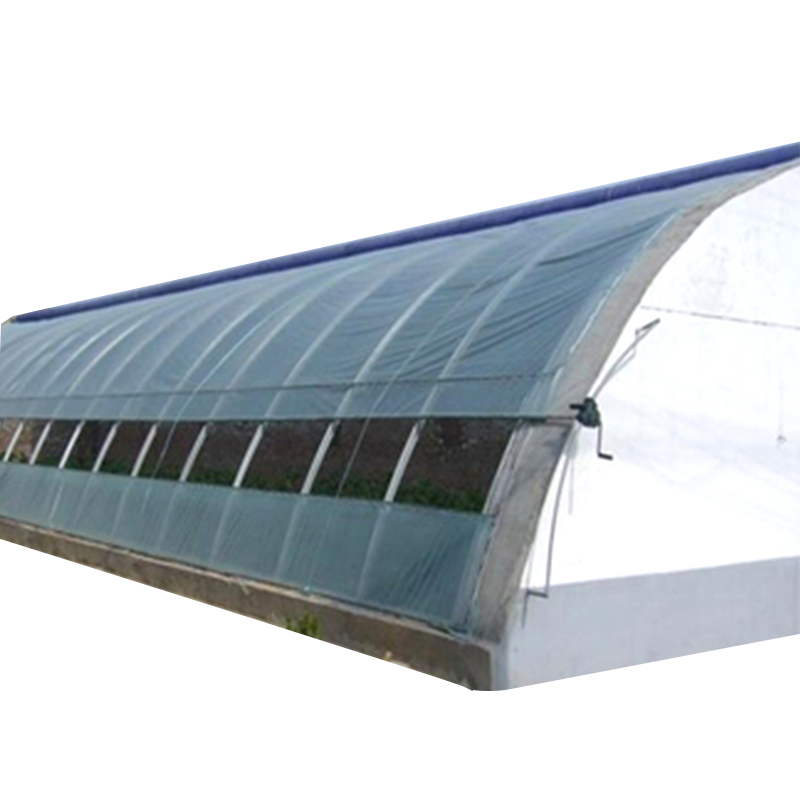

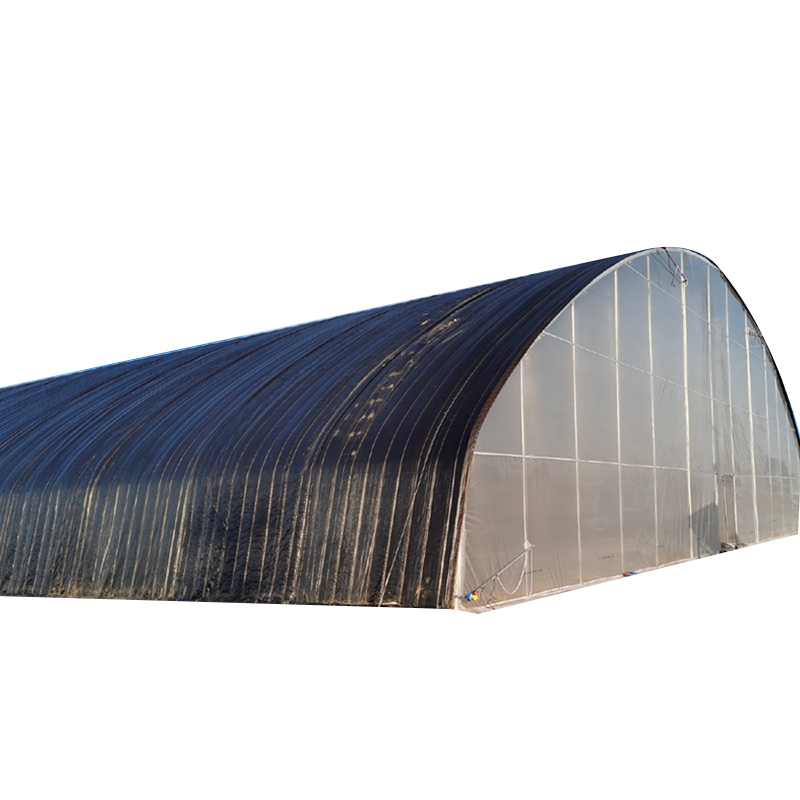

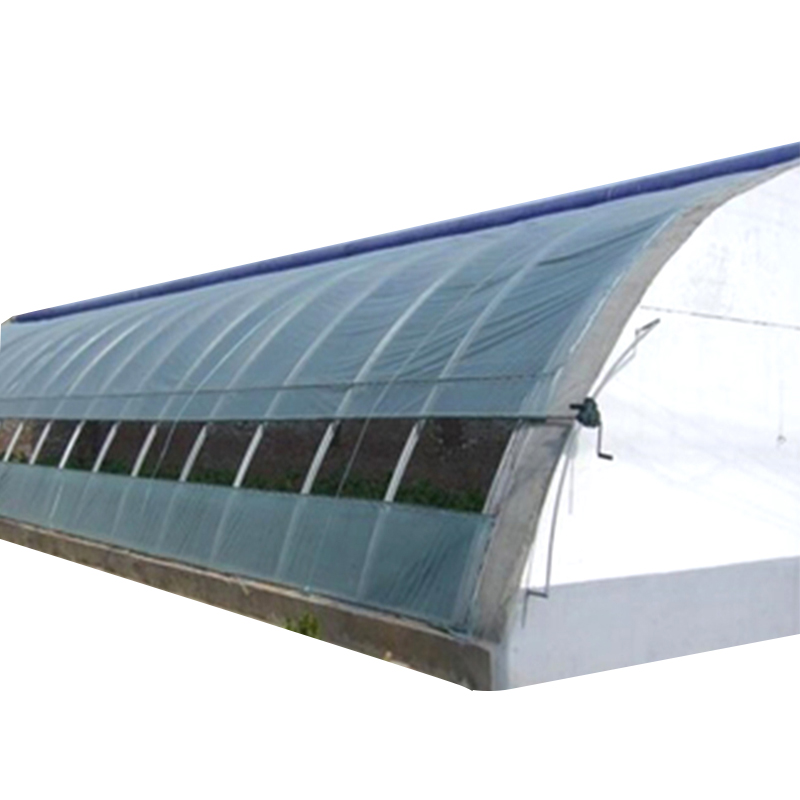

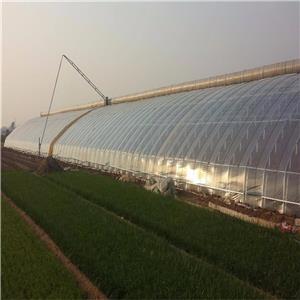

Compact Arch-shaped Single-span Solar Greenhouse

1. Executive Summary of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

The Compact Arch-Shaped Single-Span Solar Greenhouse represents a breakthrough in small-scale protected agriculture, combining space efficiency, superior thermal performance, and structural resilience in a cost-effective package. Designed for commercial growers, research institutions, and serious hobbyists, this greenhouse delivers 90% of the functionality of larger structures in just 60% of the space.

Key innovations include:

Advanced arch geometry optimizing light capture and snow shedding

Integrated solar thermal systems reducing heating requirements by 65%

Modular construction enabling rapid deployment and expansion

Smart climate compatibility for precision agriculture applications

2. Architectural Design & Engineering of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

2.1 Structural Geometry

Precision-arched framework (180° semicircular profile)

Minimizes structural members while maximizing interior volume

Aerodynamic coefficient (Cd) of 0.32 reduces wind loads

Single-span clearspan design (no internal supports)

Maximum usable growing area

Simplified mechanization access

2.2 Dimensional Specifications

| Parameter | Value | Benefit |

|---|---|---|

| Standard Span | 4m | Optimal light penetration |

| Eave Height | 1.8m | Ergonomic working space |

| Peak Height | 2.8m | Thermal stratification buffer |

| Module Length | 2m increments | Flexible expansion |

2.3 Material Science

Frame: 1.5mm galvanized steel (G550, Z275 coating)

Cladding: 8mm UV-stabilized polycarbonate (10-year warranty)

Foundation: Ground screw system (3-hour installation)

3. Solar Performance Systems of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

3.1 Light Optimization

94% PAR transmission through nano-coated glazing

Light diffusion >70% (reduced plant shading)

Reflective floor coating (92% albedo) boosts underleaf illumination

3.2 Thermal Management

Active Systems:

200L solar thermal water storage (2.1kW heat capacity)

Underground air circulation (GHE) pipes (40cm diameter)

Passive Systems:

Phase-change material panels (18°C transition point)

Retractable double-layer insulation (R-value 3.4)

3.3 Energy Balance

| Period | Heat Gain (kWh/m²/day) | Heat Loss (kWh/m²/day) |

|---|---|---|

| Winter | 3.8 | 2.1 |

| Summer | 5.2 | 4.3 |

| Shoulder | 4.5 | 3.0 |

4. Structural Performance of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

4.1 Load Capacity

Snow load: 50kg/m² (design), 75kg/m² (ultimate)

Wind resistance: 120km/h (33m/s) sustained

Seismic: Zone 4 compliant (IBC 2018)

4.2 Durability Metrics

Corrosion resistance: 5000-hour salt spray test

Impact resistance: Withstands 25mm hail at 30m/s

Service life: 20+ years (structural), 12 years (cladding)

5. Climate Control Systems

of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

5.1 Ventilation of compact solar greenhouse ,single-span solar greenhouse and arch-shaped solar greenhouse

Automatic roof vents (30% of floor area)

Sidewall louvers with insect screens

Solar-powered exhaust fans (200m³/hr capacity)

5.2 Supplemental Systems

LED interlighting (150μmol/m²/s PPFD)

CO₂ enrichment (800-1200ppm control)

Drip irrigation with moisture feedback

6. Agricultural Performance

6.1 Crop Trials Data

| Crop | Yield Increase | Season Extension |

|---|---|---|

| Lettuce | +38% | 11 months |

| Tomatoes | +27% | 9 months |

| Strawberries | +45% | Year-round |

| Herbs | +52% | Perennial |

6.2 Space Utilization

Vertical systems: 3.2m² equivalent/m² floor

Mobile benches: 85% usable area

Aisle efficiency: 0.5m minimum width

7. Installation & Maintenance

7.1 Construction Timeline

Site prep: 4 hours (grading+marking)

Foundation: 3 hours (screw piles)

Frame erection: 6 hours (2-person crew)

Cladding: 4 hours

Systems install: 8 hours

7.2 Maintenance Protocol

Daily: Check automated systems

Weekly: Clean glazing surfaces

Monthly: Lubricate moving parts

Annual: Structural inspection

8. Economic Analysis

8.1 Cost Structure

| Component | % of Total | Lifespan |

|---|---|---|

| Structure | 58% | 20 years |

| Cladding | 22% | 12 years |

| Systems | 20% | 8-10 years |

8.2 ROI Calculation

Initial investment: $85/m²

Annual savings: +35/m² (yield)

Payback period: 2.3 years (commercial lettuce)

9. Case Studies

9.1 Urban Farm Installation (Toronto)

Configuration: 6×4m (24m²)

Production: 1.2 tons/year leafy greens

Energy autonomy: 92% achieved

9.2 Research Station (Norway)

Winter performance: -25°C external, +8°C internal

Light transmission: 88% at 15° solar altitude