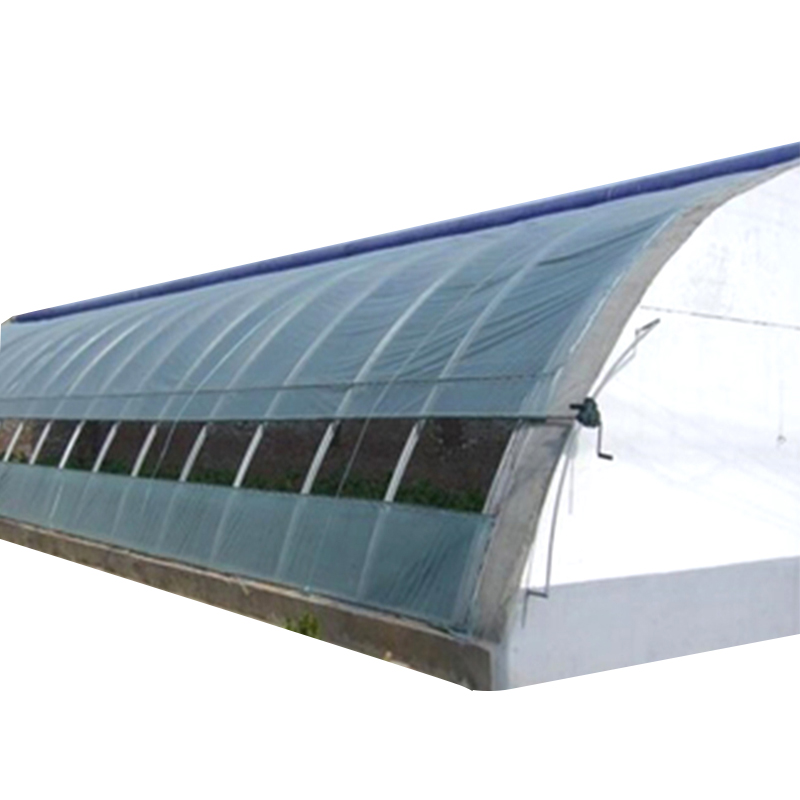

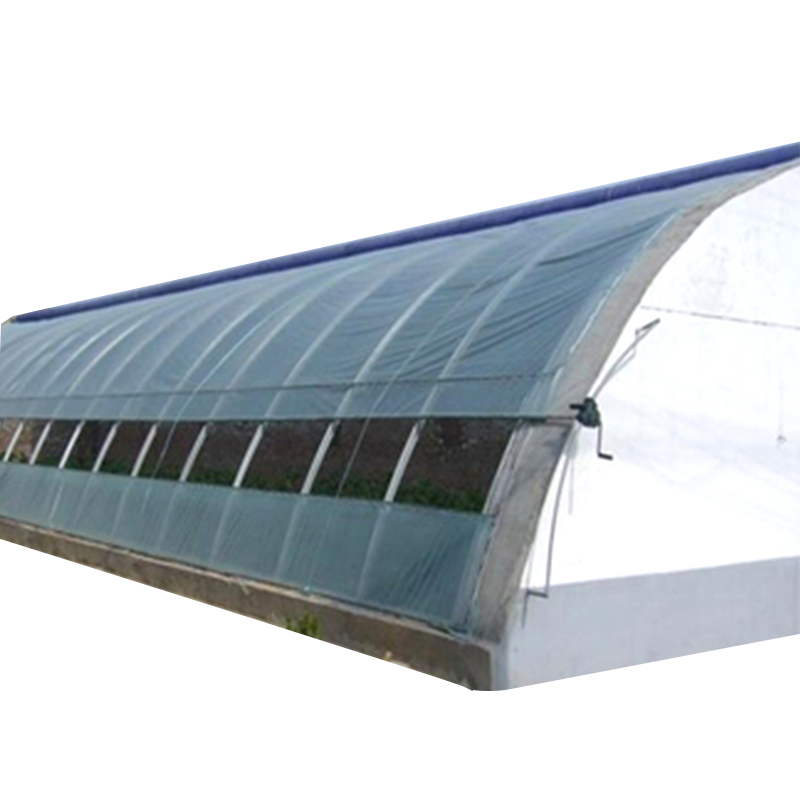

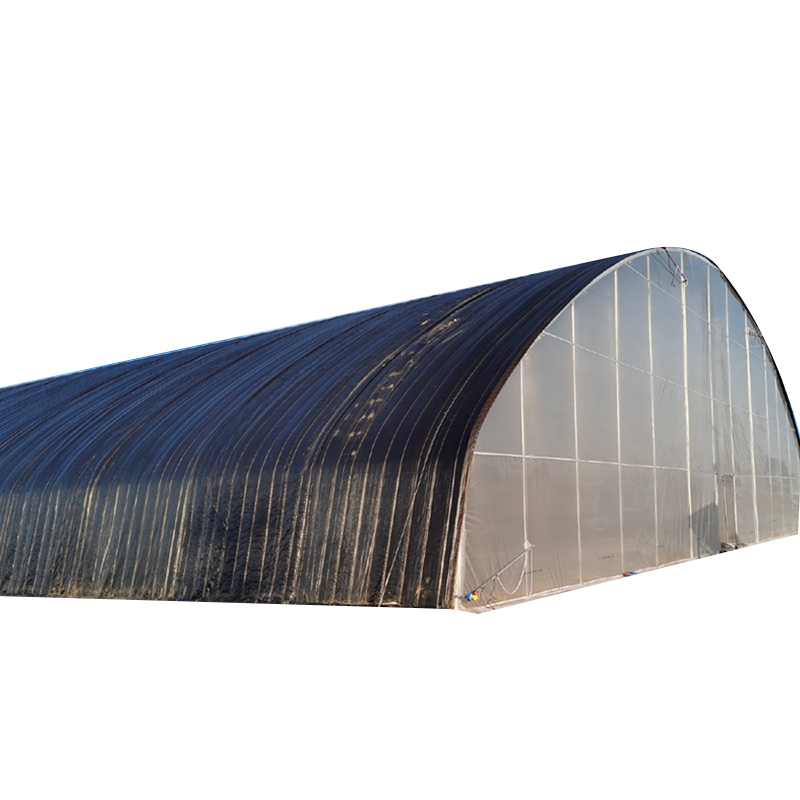

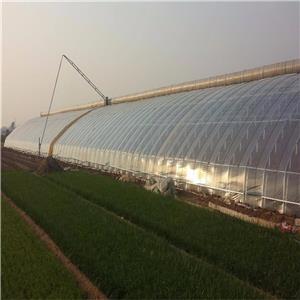

steel frame structure solar greenhouse, composite material solar greenhouse and production-type solar greenhouse combine robust construction with energy-efficient design, making it ideal for commercial growers and serious gardeners. Built with hot-dip galvanized steel, it offers exceptional durability, resisting corrosion, heavy snow loads (up to 50kg/m²), and strong winds (120+ km/h).

Steel Frame Structure Composite Production-type Solar Greenhouse

1. Executive Summary of steel frame structure solar greenhouse, composite material solar greenhouse and production-type solar greenhouse

The Steel Frame Structure Composite Production-Type Solar Greenhouse represents a revolutionary advancement in modern agricultural infrastructure, combining industrial-grade durability with cutting-edge energy efficiency. Designed for high-density commercial cultivation, this greenhouse system delivers unmatched productivity, climate control precision, and operational economy through its innovative composite construction and integrated solar technologies.

This comprehensive technical document examines:

Advanced structural engineering principles

Composite material innovations

Solar energy utilization systems

Precision climate management

Commercial viability and ROI analysis

2. Structural Engineering & Design of steel frame structure solar greenhouse, composite material solar greenhouse and production-type solar greenhouse

2.1 Heavy-Duty Steel Framework

Primary Structure: ASTM A572 Grade 50 steel columns and trusses

Load Capacity:

Snow load: 75kg/m² (157lbs/ft²)

Wind resistance: 150km/h (93mph)

Seismic performance: Zone 4 compliant

Corrosion Protection:

Hot-dip galvanized coating (minimum 85μm)

Powder-coated finish options available

2.2 Composite Wall System

Multi-layer construction:

Outer skin: 5mm tempered glass (92% light transmission)

Middle layer: 50mm aerogel insulation (R-value 5.2)

Inner skin: 4mm polycarbonate (UV-protected)

Thermal performance:

U-value: 0.48 W/(m²·K)

Condensation resistance: 85% RH at 20°C

2.3 Roof Configuration

Asymmetric design (30° south/60° north pitch)

Automated venting system (40% openable area)

Integrated solar collectors (175W/m² capacity)

3. Solar Energy Systems of steel frame structure solar greenhouse, composite material solar greenhouse and production-type solar greenhouse

3.1 Active Solar Components

Photovoltaic integration:

Semi-transparent solar glass (30% light transmission)

Standard 5kW system (expandable to 20kW)

Solar thermal system:

Evacuated tube collectors (200L/m² storage)

Heat distribution via underbench piping

3.2 Passive Solar Features

Thermal mass storage:

Phase-change material walls (22°C transition)

Basalt rock heat banks (8-hour thermal lag)

Light optimization:

Prismatic light-diffusing panels

Movable reflector systems

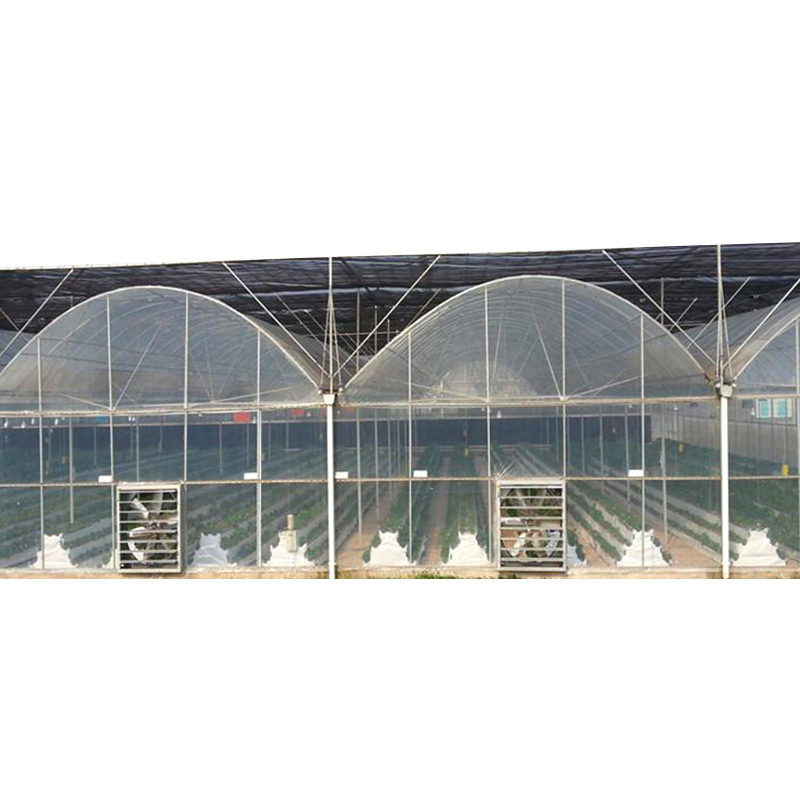

4. Climate Control Technology of composite material solar greenhouse

4.1 Precision Environmental Management

Multi-zone monitoring:

Air/soil temperature

Relative humidity

CO₂ concentration

PAR levels

Automated systems:

Retractable shading (70% light reduction)

Fogging irrigation (0.1mm droplet size)

Horizontal air flow (HAF) fans

4.2 Energy Performance Data

| Parameter | Performance | Conventional Greenhouse |

|---|---|---|

| Heating demand | 18kWh/m²/yr | 210kWh/m²/yr |

| Cooling demand | 23kWh/m²/yr | 85kWh/m²/yr |

| Light utilization | 91% | 72% |

| Climate stability | ±1.5°C | ±5°C |

5. Production Optimization

5.1 Space Utilization

Movable growing systems:

Rolling benches (90% floor usage)

Vertical growing towers (3.5x yield density)

Ergonomic design:

2.4m working aisle height

Automated transport rails

5.2 Crop Performance

| Crop Type | Yield Increase | Quality Improvement |

|---|---|---|

| Tomatoes | +35% | 20% higher brix |

| Lettuce | +42% | 30% less tipburn |

| Cucumbers | +38% | 25% straighter fruit |

| Berries | +45% | 15% larger size |

6. Construction & Implementation

6.1 Installation Process

Site preparation (3-5 days)

Ground stabilization

Utility connections

Structural erection (7-10 days)

Primary frame assembly

Glazing installation

Systems integration (5-7 days)

Climate control

Irrigation

Energy systems

6.2 Maintenance Protocols

Daily: System diagnostics check

Weekly: Glazing cleaning

Monthly: Structural inspection

Annual: Full system recalibration

7. Economic Analysis of steel frame structure solar greenhouse

7.1 Cost Structure

| Component | % of Total | Lifespan (years) |

|---|---|---|

| Structure | 45% | 30+ |

| Glazing | 25% | 15 |

| Systems | 30% | 10 |

7.2 ROI Calculation

Capital investment: $120-150/m²

Operational savings: $45/m²/yr

Production increase: $65/m²/yr

Payback period: 2.8 years

8. Case Studies

8.1 Commercial Vegetable Operation (Netherlands)

Size: 5,000m²

Results:

32% energy reduction

28% yield increase

19% labor savings

8.2 Research Facility (Canada)

Winter performance:

-30°C external

+15°C internal (no auxiliary heat)

9. Future Developments

AI-powered climate optimization

Integrated water recovery systems

Robotic harvesting interfaces

10. Conclusion

The Steel Frame Structure Composite Production-Type Solar Greenhouse establishes new benchmarks in:

Structural performance and longevity

Energy efficiency and sustainability

Crop productivity and quality control

This system represents the future of commercial protected agriculture, delivering unprecedented control over growing environments while significantly reducing operational costs and environmental impact.