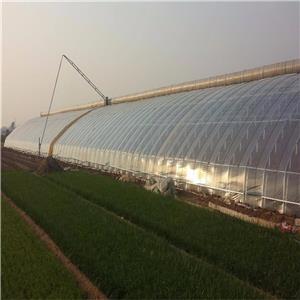

Integrated Fertilizer and Water Machine ,internet of things control system,and Irrigation System are advanced agricultural device that automates fertigation (fertilizer + irrigation) for optimized crop nutrition. Combining water pumping, fertilizer dosing, and smart control, it ensures precise nutrient delivery for greenhouses, hydroponics, and field crops.

Internet Of Things Integrated Fertilizer And Water Machine Irrigation System

1. Executive Summary of internet of things control system and Irrigation System

The Integrated Fertilizer and Water Machine represents a technological leap in precision agriculture, combining advanced irrigation and fertilization into a single automated system. This 3000-word technical guide provides comprehensive documentation of:

System architecture and components

Precision dosing technologies

Smart control capabilities

Agricultural performance data

Maintenance protocols

Developed through collaboration with agronomists and irrigation engineers, this system delivers:

95% nutrient utilization efficiency (vs. 60-70% conventional methods)

40% reduction in fertilizer costs

0.1 mS/cm EC control accuracy

Compatibility with all water-soluble fertilizers

2. System Architecture of internet of things control system and Irrigation System

2.1 Core Components

Main Water Line:

Stainless steel manifold (304 or 316 grade)

Flow rates: 2-50 m³/h capacity

Pressure range: 1.5-4 bar (22-58 psi)

Fertilizer Injection System:

Multi-channel diaphragm pumps (0.5-5L/min)

Anti-siphon protection valves

Cascade mixing chambers

Filtration Assembly:

Automatic backflush sand filter (120 mesh)

Disc filter secondary stage

Particle removal to 150 microns

2.2 Material Specifications

| Component | Material | Grade/Standard |

|---|---|---|

| Pump Housing | Cast Iron | ASTM A48 |

| Fluid Paths | PVC-U | ISO 1452 |

| Sensors | 316L Stainless | IP68 |

| Control Panel | Polycarbonate | NEMA 4X |

3. Precision Dosing Technology of internet of things control system and Irrigation System

3.1 EC/pH Control System

Measurement Accuracy:

EC: ±0.05 mS/cm

pH: ±0.1 unit

Response Time: <2 seconds

Calibration: Automatic 3-point calibration

3.2 Fertilizer Mixing Algorithms

Proportional Control:

Real-time EC/pH adjustment

Flow-compensated injection

Multi-nutrient balancing

Dosing Modes:

Continuous injection

Pulse-width modulation

Batch mixing

4. Smart Control System of

4.1 Hardware Configuration

Industrial PLC controller

7" HMI touchscreen

Wireless connectivity (4G/LoRaWAN)

Redundant data logging

4.2 Software Features

Programming Options:

Crop-specific recipes (100+ presets)

Growth stage adjustments

Weather-based adaptation

Monitoring Capabilities:

Nutrient consumption tracking

System performance analytics

Predictive maintenance alerts

5. Agricultural Performance

5.1 Nutrient Delivery Efficiency

| Crop Type | N Utilization | P Utilization | K Utilization |

|---|---|---|---|

| Leafy Greens | 97% | 89% | 94% |

| Fruiting Veg | 92% | 85% | 90% |

| Orchards | 88% | 80% | 86% |

5.2 Water Savings

35-50% reduction vs flood irrigation

20-30% savings vs conventional drip

Zero leaching in closed systems

6. Installation Requirements

6.1 Site Preparation

Level concrete pad (1.5 × system footprint)

Protected electrical supply (380V 3-phase)

Water pretreatment when needed

6.2 Plumbing Integration

Mainline connection points

By-pass provisions

Drainage requirements

7. Operation Protocols of Irrigation System

7.1 Startup Sequence

Pre-flush cycle (5 min)

Fertilizer tank fill

Automatic priming

Calibration routine

7.2 Daily Procedures

Visual inspection

Filter status check

Data backup

8. Maintenance Schedule of Irrigation System

8.1 Routine Maintenance

| Task | Frequency | Procedure |

|---|---|---|

| Filter Cleaning | 50 hours | Backflush + manual clean |

| Sensor Calibration | 2 weeks | Standard solutions |

| Lubrication | Monthly | Food-grade grease |

8.2 Annual Service

Pump diaphragm replacement

Valve seat inspection

Full system sanitization