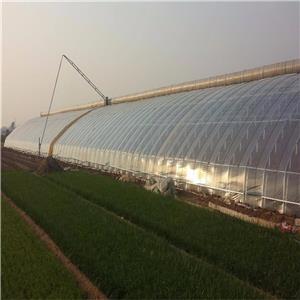

electric sunshade system and automatic thermal insulation quilt system are automated shading solution that optimizes light intensity and temperature in greenhouses. Using motorized screens and smart sensors, it provides precise shade control for improved crop growth and energy efficiency.

1. Introduction to electric sunshade system and automatic thermal insulation quilt system

Modern greenhouse operations require precise environmental control to optimize plant growth while minimizing energy consumption. The electric sunshade system has emerged as an essential component in advanced greenhouse climate management, offering automated control over light intensity and temperature. These systems consist of motorized shading screens that can be extended or retracted based on real-time environmental conditions or predetermined schedules.

Electric sunshade systems serve multiple critical functions:

Solar radiation management

Temperature regulation

Energy conservation

Light diffusion enhancement

Crop protection from excessive sunlight

2. System Components and Architecture of electric sunshade system and automatic thermal insulation quilt system

2.1 Core Components

The complete electric sunshade system comprises several integrated elements:

Shading Screen Material:

Knitted or woven polyester fabric

Aluminum-coated or laminated surfaces

Various shading percentages (30%-90%)

UV-stabilized for longevity

Drive System:

24V DC electric motors

Stainless steel drive cables

Aluminum track systems

Gearboxes with overload protection

Control System:

Light intensity sensors

Temperature sensors

Programmable logic controller (PLC)

User interface panel

Support Structure:

Galvanized steel support wires

Mounting brackets

Tensioning devices

2.2 System Configurations

Single-Layer Systems:

Basic light control

50-70% shading capacity

Most economical option

Double-Layer Systems:

Combined shading and energy saving

Blackout capability

Improved insulation properties

Retractable Roof Systems:

Full roof opening capability

Maximum ventilation potential

Highest light transmission when open

3. Technical Specifications

3.1 Performance Parameters

| Specification | Standard Range | Premium Options |

|---|---|---|

| Shading Rate | 30%-90% | Adjustable 10%-95% |

| Motor Power | 100-200W | 300W (heavy-duty) |

| Operation Speed | 0.5-1.2 m/min | 1.5-2.0 m/min |

| Noise Level | <50 dB | <40 dB |

| Screen Life | 8-10 years | 12-15 years |

3.2 Electrical Requirements

Voltage: 24V DC (standard), 48V DC (large systems)

Power Consumption: 0.5-2.0 kWh/day (typical)

Safety Features: Overcurrent protection, emergency stop

Connectivity: RS485, Modbus, wireless options

4. Operational Principles

4.1 Control Strategies

Light-Based Control:

PAR sensor input (μmol/m²/s)

Adjustable setpoints for different crops

Gradual adjustment algorithms

Temperature-Based Control:

Canopy temperature monitoring

Integrated with ventilation systems

Heat stress prevention protocols

Hybrid Control:

Combines multiple parameters

AI-based optimization

Weather forecast integration

4.2 Movement Mechanisms

Roller Systems:

Fabric wound on aluminum tubes

Smooth unrolling operation

Automatic tension maintenance

Folding Systems:

Accordion-style movement

Compact storage

Uniform light distribution

5. Benefits and Advantages of automatic thermal insulation quilt system

5.1 Crop Production Benefits

Prevents sunburn damage to leaves and fruits

Maintains optimal leaf temperature

Reduces water stress

Enables year-round production

Improves crop quality and consistency

5.2 Energy Efficiency

Reduces cooling requirements by 40-60%

Lowers HVAC operational costs

Provides insulation in cold weather

Minimizes light pollution at night

5.3 Operational Advantages

Fully automated operation

Remote monitoring capability

Minimal maintenance requirements

Compatible with most greenhouse types

Scalable for any size operation

6. Installation Considerations

6.1 Structural Requirements

Minimum headroom: 30cm above crop

Support wire spacing: 50-70cm

Load capacity: 1.5-3.0 kg/m²

Clearance for maintenance access

6.2 Electrical Installation

Dedicated circuit requirements

Surge protection devices

Proper grounding

Cable management systems

6.3 Integration with Other Systems

Ventilation coordination

Irrigation system synchronization

Lighting system compatibility

Data logging integration

7. Maintenance and Troubleshooting

7.1 Routine Maintenance

Monthly inspection of moving parts

Annual lubrication of drive components

Screen cleaning (bi-annual)

Sensor calibration (annual)

7.2 Common Issues and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Uneven movement | Tension imbalance | Adjust end stops |

| Motor overheating | Voltage fluctuation | Check power supply |

| Screen wrinkling | Improper installation | Re-tension system |

| Sensor errors | Dirty optics | Clean sensor surface |