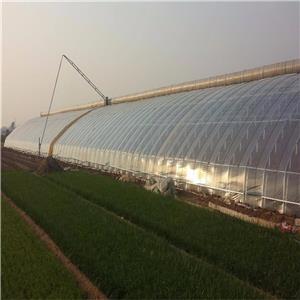

Multi-span glass greenhouse consists of multiple connected bays, forming a large, uninterrupted growing area. This design maximizes space efficiency, reduces construction costs, and improves thermal performance by minimizing external wall exposure. The structure typically uses tempered or laminated glass for high light transmission and durability.

Float glass greenhouse is constructed using float glass, a high-quality, distortion-free glass produced by floating molten glass on a bed of molten tin. This results in exceptional clarity and uniform thickness, optimizing sunlight diffusion for plant growth.

Multi-span Compact Hollow Float Glass Greenhouse

1. Introduction of multi-span glass greenhouse and float glass greenhouse

The Multi-Span Compact Hollow Float Glass Greenhouse represents a revolutionary advancement in modern horticultural infrastructure. Combining the space efficiency of multi-span design with the superior optical and thermal properties of hollow float glass, this greenhouse system offers unmatched performance for commercial growers, research institutions, and urban farming initiatives.

This 3000-word guide provides an in-depth exploration of its design principles, technological features, operational benefits, and practical applications in contemporary agriculture.

2. Structural Design and Materials of multi-span glass greenhouse and float glass greenhouse

Multi-Span Architecture

The multi-span configuration connects multiple greenhouse bays under a single roof structure, offering several advantages:

Space Optimization: Eliminates unnecessary walls between sections, maximizing usable growing area

Structural Efficiency: Reduced material usage per square meter compared to standalone units

Climate Uniformity: Creates more stable environmental conditions across larger areas

Operational Convenience: Allows seamless movement of personnel and equipment

Typical spans range from 6-12 meters with gutter heights of 4-6 meters, balancing light penetration with operational space.

Hollow Float Glass Technology

The greenhouse utilizes specially engineered hollow float glass panels:

Construction: Two layers of float glass separated by a vacuum or inert gas cavity

Optical Properties: Maintains 90-92% light transmission while diffusing sunlight evenly

Thermal Performance: R-values up to 1.5, significantly better than single-pane alternatives

Durability: Resistant to thermal stress and impact damage

Condensation Control: Inner surface temperatures remain closer to ambient air temperature

Compared to traditional glass or polycarbonate, this solution provides superior insulation without compromising light quality.

Frame and Support Systems

The structural framework incorporates:

Galvanized Steel: Primary load-bearing components with 20-30 year corrosion resistance

Aluminum Alloys: For glazing bars and secondary structural elements

Thermal Breaks: Insulating spacers between metal components to prevent heat bridging

Modular Connections: Allows for future expansion or reconfiguration

3. Climate Control and Automation of multi-span glass greenhouse and float glass greenhouse

Temperature Regulation

An integrated system maintains optimal temperatures year-round:

Heating: Hydronic floor heating combined with overhead hot water pipes

Cooling: Pad-and-fan systems with optional adiabatic cooling

Thermal Screens: Automated retractable screens with varying shading percentages

Phase Change Materials: Some models incorporate PCMs in walls for thermal buffering

Humidity Management

Precision humidity control prevents disease while promoting growth:

High-Pressure Fogging: 5-10 micron droplets for gentle humidification

Dehumidification: Condensation on chilled surfaces or desiccant systems

Ventilation Control: Algorithm-driven vent opening strategies

Ventilation Systems

Dual-mode ventilation ensures proper air exchange:

Natural Ventilation: Continuous ridge vents with insect screens

Mechanical Ventilation: EC fans with variable speed control

Air Circulation: Horizontal airflow fans spaced every 15-20 meters

Lighting Solutions

Supplemental lighting enhances production:

LED Arrays: Custom spectra for different crop types

Light Movers: Optimize photon distribution

Dynamic Control: Adjusts intensity based on natural light levels

4. Energy Efficiency and Sustainability of multi-span glass greenhouse and float glass greenhouse

Insulation Properties

The hollow glass design provides:

U-value: 1.1-1.3 W/m²K (superior to double-pane glass)

Nighttime Heat Retention: Up to 30% better than conventional greenhouses

Reduced Condensation: Maintains clearer glazing for winter light transmission

Solar Energy Integration

Renewable energy solutions include:

Semi-Transparent PV: Integrated into roof sections

Thermal Collectors: Heat storage for winter use

Dynamic Shading: PV-integrated movable screens

Water Management

Closed-loop systems maximize efficiency:

Rainwater Harvesting: 80-90% of roof runoff captured

Condensate Recovery: Up to 5L/m²/day in humid conditions

Hydroponic Integration: Recirculating nutrient delivery

5. Applications and Benefits of multi-span glass greenhouse and float glass greenhouse

Commercial Agriculture

Vegetable Production: 20-30% higher yields than conventional designs

Floriculture: Superior flower quality due to optimized light diffusion

Nursery Operations: Uniform conditions for propagation

Research and Education

Controlled Environment Studies: Precise parameter manipulation

Plant Breeding: Stable conditions for genetic research

Educational Demonstrations: Showcase of sustainable technologies

Urban and Vertical Farming

Rooftop Installations: Compact footprint for city locations

Stacked Growing Systems: Integration with vertical farming tech

Local Food Production: Year-round harvests near population centers

6. Installation and Maintenance of multi-span glass greenhouse and float glass greenhouse

Construction Process

Site Preparation: Leveling and foundation work (2-4 weeks)

Structural Erection: Primary framework installation (3-6 weeks)

Glazing: Glass panel mounting (4-8 weeks)

Systems Integration: 2-4 weeks for full commissioning

Maintenance Requirements

Daily: System diagnostics checks

Weekly: Glass surface inspections

Monthly: Mechanical system servicing

Annual: Structural integrity assessment

7. Future Trends and Innovations of multi-span glass greenhouse and float glass greenhouse

Emerging technologies include:

Smart Glass: Electrochromic glazing for dynamic light control

AI Optimization: Machine learning for climate prediction

Carbon Capture: Integrated photosynthesis enhancement

Robotic Systems: Automated harvesting and maintenance

8. Conclusion of multi-span glass greenhouse and float glass greenhouse

The Multi-Span Compact Hollow Float Glass Greenhouse represents the pinnacle of modern protected agriculture technology. By combining space-efficient multi-span architecture with advanced hollow glass glazing, this system delivers unparalleled light quality, energy efficiency, and climate control precision.

As global agriculture faces increasing challenges from climate change and urbanization, this greenhouse solution offers a sustainable path forward - enabling higher yields, better resource efficiency, and year-round production in diverse environments. Its adaptability makes it equally valuable for commercial growers, research institutions, and urban farming initiatives seeking to push the boundaries of what's possible in controlled environment agriculture.

The integration of smart technologies and renewable energy systems positions this design as a future-proof investment that will continue to deliver value as agricultural technologies evolve in the coming decade.